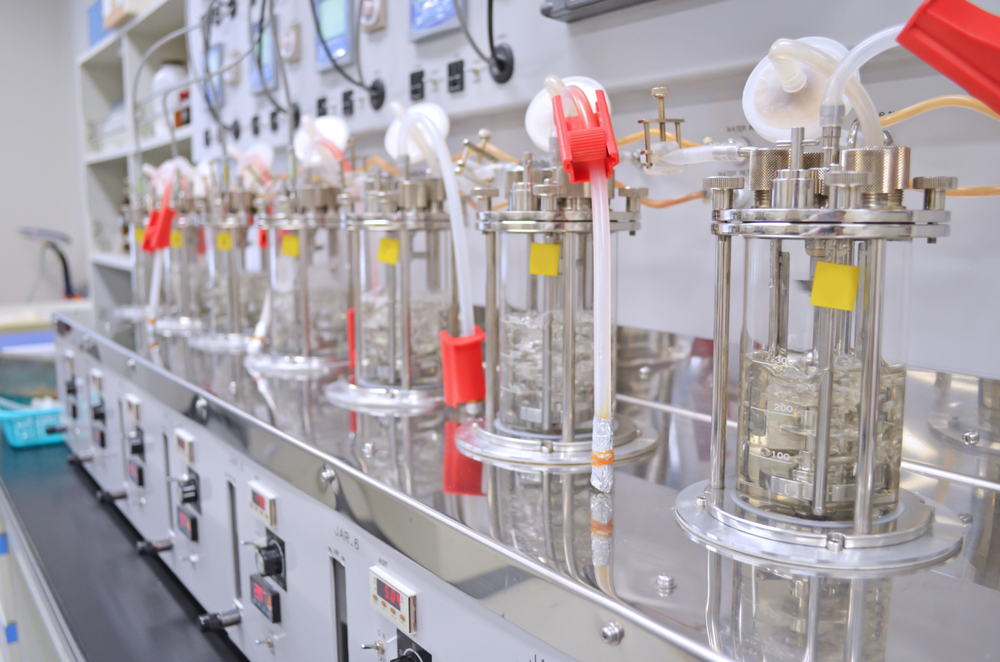

Fermentation is a biologically active process that metabolizes organic products in a contained environment. Industrial fermentation typically takes place in a sealed bioreactor comprised of multiple components, including: air inlets, a mechanical agitation system, and sensitive sample inlets for process monitoring. Fermenters are continuously monitored to acquire data on sample gas uptake and dissolved species, providing the requisite information for calculating the sample’s respiratory coefficients, and both oxygen uptake and carbon production rates.

Gas analysers are typically used to assess this information, providing product yield and process insights relating to agitation efficiency, aeration, and the bioreactor’s feed distribution.

This article will explore the use of gas analysers for fermentation monitoring in more detail:

Off-Gas Analysis in Bioreactor Monitoring

Gas analysers for fermentation monitoring provide real-time analysis of sample off-gas for species that are critical to a fermenter’s product yield, particularly oxygen (O2) and carbon dioxide (CO2) for aerobic processes, and typically dihydrogen (H2) and methane (CH4) in anaerobic processes. This information is used to obtain the respiratory coefficient of a fermentation process as a product of time and space. Dynamic process monitoring of multiple species across multiple reactors requires multiple-stream analysis to quantitatively assess the gas production and uptake rates for several gas and vapor species in real-time.

Read more about our Gas Analysis Applications

Gas analysers for fermentation monitoring provide real-time analysis of sample off-gas for species that are critical to a fermenter’s product yield, particularly oxygen (O2) and carbon dioxide (CO2) for aerobic processes, and typically dihydrogen (H2) and methane (CH4) in anaerobic processes. This information is used to obtain the respiratory coefficient of a fermentation process as a product of time and space. Dynamic process monitoring of multiple species across multiple reactors requires multiple-stream analysis to quantitatively assess the gas production and uptake rates for several gas and vapor species in real-time.

Off gas data is integral for fermentation monitoring, but it does not provide information pertaining to a bioreactor’s stirring efficiency or feed distribution. These measurements must be calculated using a dissolved species gas analyzer.

For dissolved species analysis, special probes that sample through permeable submerged membranes are employed and supplied as part of a dedicated dissolved species gas analyzer, the HPR-40 DSA or as inlet attachments for the QIC BioStream system.

These gas analysers are routinely used to monitor fermentation product yields for ethanols, lactic acid, hydrogen gas, and more.

Gas Analyzers from Hiden Analytical

Hiden Analytical is a leading developer of mass spectrometry equipment for a range of industrial processes. We provide gas analysers for both off gas and dissolved species monitoring in fermentation components.

If you would like any more information about our gas analyzers for fermentation monitoring processes, please do not hesitate to contact us.