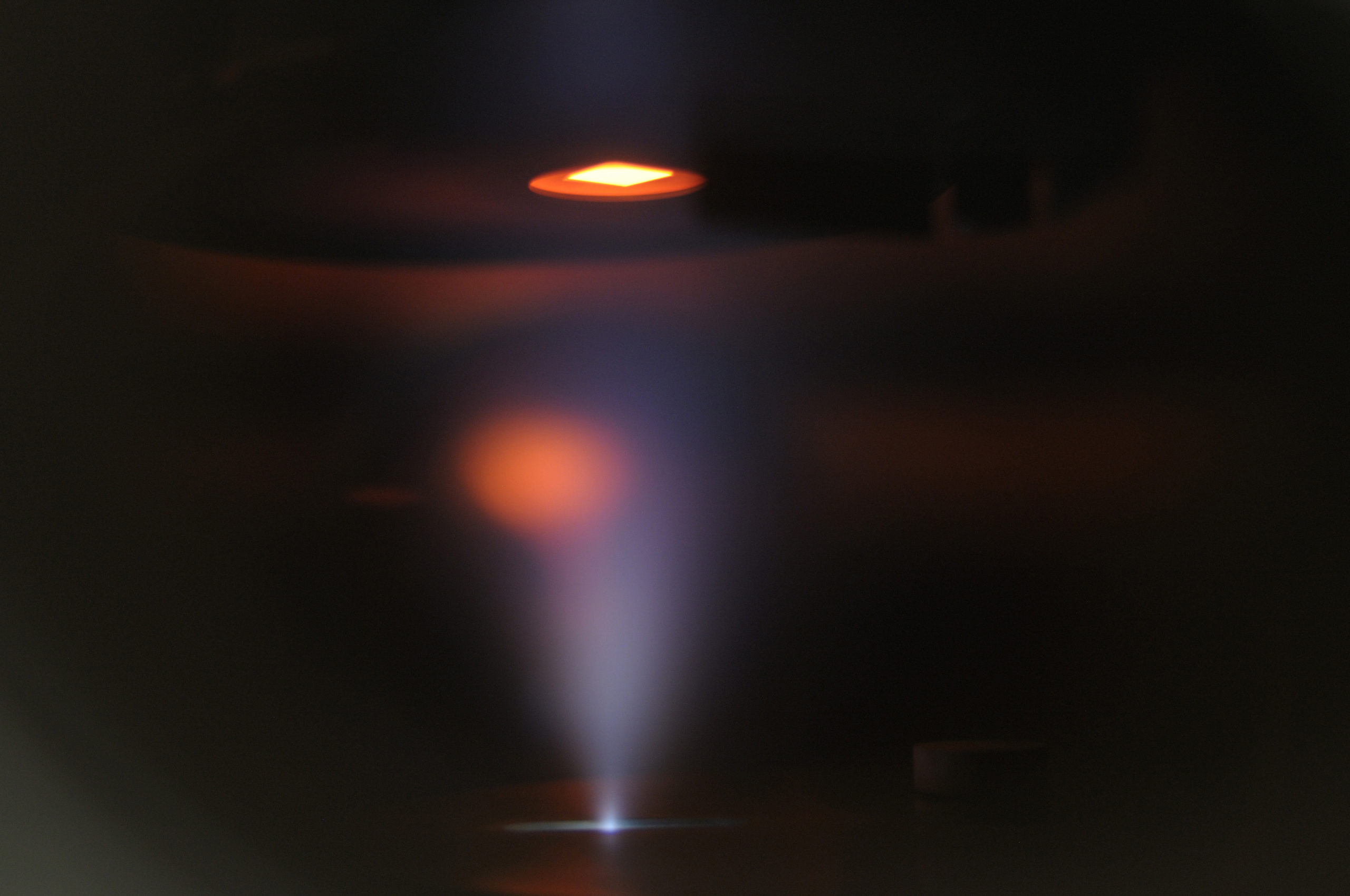

Plasma Deposition: Magnetron Sputtering

Analytical systems for plasma deposition

Hiden Analytical plasma analysis systems give unparalleled insight into magnetron sputtering and other plasma deposition processes.

Related Products

The term ‘plasma deposition’ encompasses various vapor deposition techniques that make use of plasma to deposit a ‘source’ material onto a substrate. Such techniques are commonly used to enhance surface properties such as hardness, chemical resistance, and adhesion; or to impart specific optical or electronic properties.

Magnetron Sputtering

Magnetron sputtering is a deposition technique in which a plasma (typically an inert gas such as argon) is magnetically confined around a ‘target’ of source material deposited onto a substrate. High energy ions in the plasma erode the target, liberating atoms from its surface. Liberated atoms, which are electrically neutral and able to escape the magnetic field, are then deposited onto the substrate, forming a thin film.

Typical magnetron sputtering processes are performed in a high vacuum environment to minimize contaminants’ presence. Confining the plasma around the target using strong magnetic fields enables more ionizing collisions between plasma electrons and gaseous neutrals near the target’s surface, increasing plasma density and producing a higher deposition rate. Also, the confinement of electrons in the plasma prevents damage caused by these electrons’ direct impact with the substrate or growing film.

Wear-resistant coatings, corrosion-resistant films, dry film lubricants, and optical and decorative films are among the typical DC magnetron sputtering applications.

Analytical Tools for Magnetron Sputtering Applications

The development of effective magnetron sputtering processes relies on accurately measuring plasma parameters like composition, density and ion energy. The Hiden EQP mass spectrometer is optimized for plasma analysis, making it the ideal tool for correlating plasma conditions in magnetron deposition processes with the properties of the resultant films achieved.

Hiden Analytical produces a range of specialized tools for plasma characterization. To find out more information about our industry-leading products, get in touch with Hiden Analytical today.

Atmospheric Plasma Analysis by Molecular Beam MS – GEC 2004 (1.38 MB)

Atmospheric Pressure Plasma Analysis by Modulated Molecular Beam MS – ICPIG 2005 (256 KB)

Ion Energy Distributions for a DC Plasma – GEC 2003 (250 KB)

Mass Analysis of CF3I Decomposition in a Surface Barrier Discharge – GEC 2011 (2.8 MB)

Mass Spectroscopy of Metastable Species during Plasma Processing – GEC 2011 (2.1 MB)

Time Resolved Ionisation Studies of HIPIMS – PSE 2006 (848 KB)

Stable DC vacuum arc plasma generation from a 100mm TiB2 cathode 1.54 MB 0 downloads

Stable DC vacuum arc plasma generation from a 100mm TiB2 cathode ...Effects of power on ion behaviours in radio-frequency magnetron sputtering of indium tin oxide (ITO) 972.00 KB 4 downloads

Effects of power on ion behaviours in radio-frequency magnetron sputtering of indium...Determination of effective Ga/N ratio to control GaN growth behavior in liquid-target reactive magnetron sputter epitaxy 8.61 MB 3 downloads

Determination of effective Ga/N ratio to control GaN growth behavior in liquid-target...Double layer acceleration of ions with differently charged states in a laser induced plasma 790.72 KB 8 downloads

Double layer acceleration of ions with differently charged states in a laser induced...The crucial role of defect structure in understanding the electrical properties of spark plasma sintered antimony doped barium stannate 1.43 MB 9 downloads

The crucial role of defect structure in understanding the electrical properties of...A comparison of plasma generation, plasma transport, and film formation for a DC vacuum arc source with Ti–X compound cathodes (X = W, C, Al, and Si) 3.16 MB 11 downloads

A comparison of plasma generation, plasma transport, and film formation for a DC...Study of process parameters and characteristics properties of W coatings deposited by rf plasma sputtering 2.70 MB 11 downloads

Study of process parameters and characteristics properties of W coatings deposited...Development of a Noninvasive Real-Time Ion Energy Distribution Monitoring System Applicable to Collisional Plasma Sheath 953.36 KB 9 downloads

Development of a Noninvasive Real-Time Ion Energy Distribution Monitoring System...Controlled Deposition of Nanostructured Hierarchical TiO2 Thin Films by Low Pressure Supersonic Plasma Jets 1.92 MB 21 downloads

Controlled Deposition of Nanostructured Hierarchical TiO2 Thin Films by Low Pressure...A comparative study of thick TiSiCN nanocomposite coatings deposited by dcMS and HiPIMS with and without PEMS assistance 2.66 MB 29 downloads

A comparative study of thick TiSiCN nanocomposite coatings deposited by dcMS and...- Vlček, J. et al. Magnetron sputtered Si–B–C–N films with high oxidation resistance and thermal stability in air at temperatures above 1500 °C. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films 26, 1101–1108 (2008).

- Vlček, J. et al. Reactive magnetron sputtering of hard Si–B–C–N films with a high-temperature oxidation resistance. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films 23, 1513–1522 (2005).

- Ehiasarian, A. P. et al. Influence of high power impulse magnetron sputtering plasma ionization on the microstructure of TiN thin films. Journal of Applied Physics 109, 104314 (2011).