Operando/in-situ spectroscopy as a powerful material characterization tool grows rapidly and shines light on various fields such as heterogeneous catalysis, electrocatalysis, photocatalysis and batteries. The characterization of chemical and structural properties of catalytic materials under working conditions provide critical information on catalytic technologies and help develop a mechanistic understanding to support further advancements in their industrial application. In this work, we present an industrial example on how tailored operando spectroscopic methodologies were utilized to provide the insights in the heterogeneous catalysis area. We describe the use of operando spectroscopic methods to investigate catalytic oxidation processes and the impacts from the presence of NOx, H2, temperature, and moisture, as well as the catalyst support.

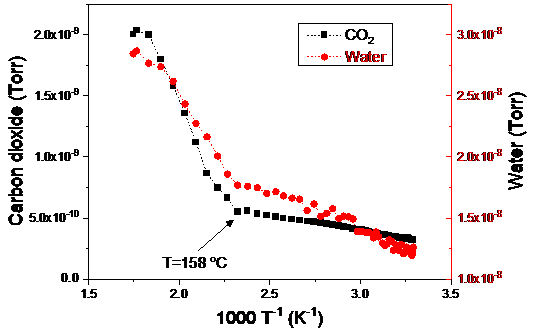

In this work, a Hiden Analytical HPR-20 mass spectrometer was used in the operando spectroscopy characterization of our diesel oxidation catalyst samples. The gas products of carbon dioxide and water were monitored at the exhaust of the catalytic reactor as the function of reaction temperature. The CO oxidation reaction under H2 (2000 ppm CO, 7200 ppm H2, and 10% O2) was investigated over a Pt/alumina catalyst. The low temperature CO2 generation was associated with the catalyst surface cleaning process with the combination of CO with an activated O* atom on the catalytic surface. After the oxidation process was activated at T > 158 oC, higher CO conversion was achieved. The Arrhenius-type plot of CO2 and water was shown in Figure 1 during a continuous temperature ramping process. A process of gas phase O2 dissociation with a higher activation energy was initiated at above 158 °C for both CO oxidation and H2 oxidation reactions.

Figure 1. Water and CO2 signals obtained from the mass spectrometer HPR-20 signals.

Figure 1. Water and CO2 signals obtained from the mass spectrometer HPR-20 signals.

This operando spectroscopic analysis provides spectroscopic evidences on fundamental mechanistic understanding of the oxidation processes over diesel oxidation catalysts (DOC) and shines light on the material and process development efforts on future DOC catalysts for low-temperature emission control to meet the new regulations. The findings include that the nitrate growth at cold-start temperatures, may take up the catalyst-support interfacial sites, which could hinder the oxidation process by losing critical O2 dissociation and/or oxygen transfer sites. The presence of small amount of hydrogen can inhibit the nitrate growth on the catalyst surface, resulting in open interfacial sites.

Project summary by: Claire Chunjuan Zhang, BASF Corporation, 25 Middlesex-Essex Tpk, Iselin, NJ 08830, USA

Paper Reference: Claire C. Zhang, Shiang Sung, Sage Hartlaub, Ivan Petrovic and Bilge Yilmaz, “Example on the Use of Operando Spectroscopy for Developing Mechanistic Insights into Industrial Catalysts and Catalytic Processes”, Catalysts, 2021, 11, 200; doi.org/10.3390/catal11020200.

Hiden Product: HPR-20

Project Summary Reference: AP-HPR-20-202131

To find out more about these products visit the HPR-20 product page or if you would like to contact us directly please Send us a Message.