Temperature programmed reduction (TPR) is a material characterization process commonly used in catalysis studies to examine the surface chemistry of metals and metal oxides under varying thermal conditions. TPR-enabled mass spectrometry equipment can acquire quantitative and qualitative data relating to the reducing gas mixtures that are made to flow over metallic samples. This process is integral to catalyst investigation as it provides accurate insights into catalyst reducibility and reaction rates in the presence of metal surfaces, informing conclusions on catalyst reproducibility and supporting quality control of existing catalytic substances by setting benchmarks or reduction profiles that ideal manufactured catalysts should adhere to.

How is TPR Performed?

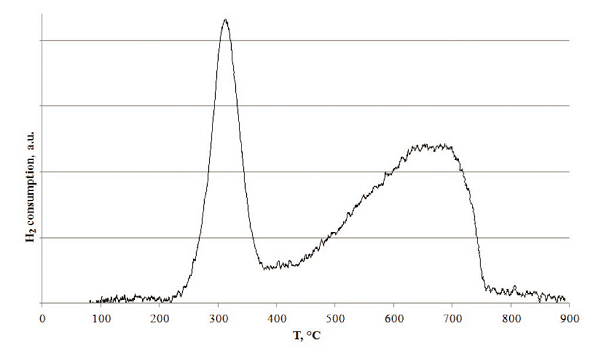

In a typical TPR experiment, a metal oxide such as nickel (NiO) is dispersed upon a surface and tested in a system known as a fixed bed reactor. A reducing gaseous mixture such as hydrogen (H2) is then made to flow across the catalyst under gradually increasing thermal conditions. This linear heating allows reduction rate to be correlated with temperature. A highly-sensitive detector continually analyses the chemical difference in atmospheric concentration at the outlet, producing an accurate picture of the maximum or peak reduction rate of the catalyst. TPR profiles produced using this method are instrumental in ascertaining a metal oxide’s potential use as a commercial or industrial catalytic material.

Physiochemical catalytic data cannot be acquired using TPR methods alone, however, which is why linear heating experiments of this methodology are typically used in conjunction with spectrometric equipment.

TPR Mass Spectrometers

TPR-enabled mass spectrometers couple a microreactor chamber and a mass spectrometer system for multiple forms of data acquisition from catalytic reaction experiments. For example, the modular CATLAB-PCS system includes a wide range of operating modes that enable multiple experimental methods for catalysis and reaction studies.

This CATLAB-PCS system features a sensitive thermocouple in the reactor bed for direct catalyst temperature measurement alongside the linear heating and reduction values gathered by the system’s intuitive software together with data acquisition from the mass spectrometer. It has template-driven software, allowing for precise and automated control of gas composition and flow rates. The standard system can be manually operated or programmed to established templates, with heating rates of up to 1000 °C in increments of 1 – 20 °C/min.

With total control of mass spectrometer parameters and heating rates to finite degrees, the CATLAB-PCS is instrumental for modern catalysis studies.

TPR Experiments with Hiden Analytical

Hiden Analytical has over 35 years’ experience in the design, manufacture, and supply of quadrupole mass spectrometers with high degrees of application specificity, with exceptional modular designs improving the bespoke nature of our laboratory instrumentation. We have a thorough understanding of established and emerging research and production processes, and are ever-focused on streamlining those procedures through the application of incredible hardware and software.

We offer a broad range of mass spectrometers for TPR studies, with additional modules for the acquisition of data unique to specific areas of research. If you would like any more information about our TPR mass spectrometers, please do not hesitate to contact us.