Products for Thin Films, Plasma and Surface Engineering

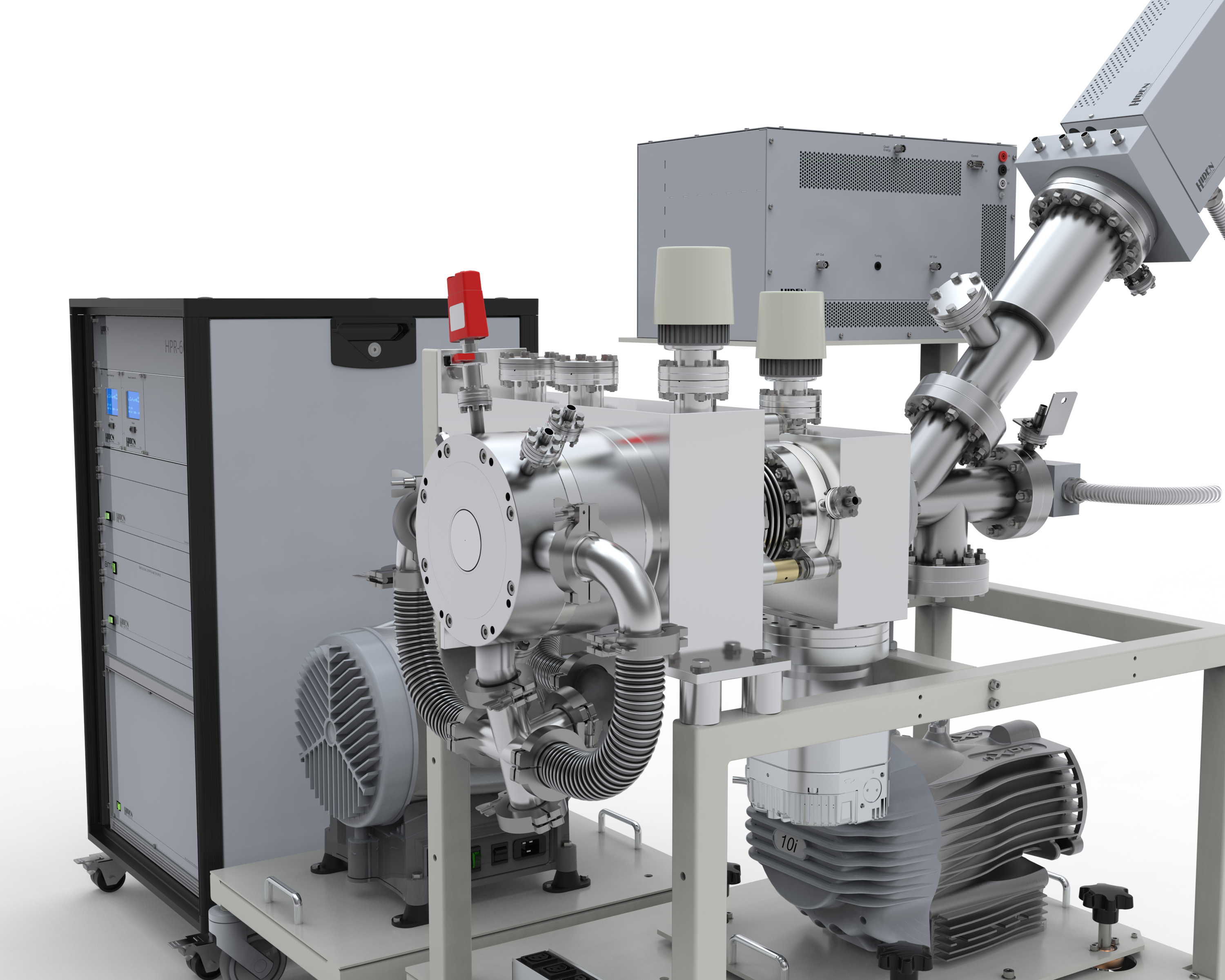

HPR-30 Series

In-Situ differentially pumped gas analyzers for vacuum process gas composition, contamination monitoring and leak detection.

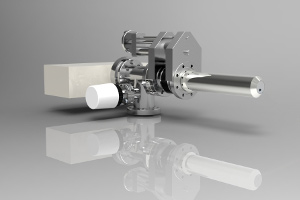

HPR-60 MBMS

The HPR-60 MBMS (molecular beam mass spectrometer) is optimised for the analysis of both positive (+ve) and negative (-ve) ions, as well as neutral and radicals, making it a robust solution for plasma and combustion analysis.

HMT

A dual mode RGA system for vacuum diagnostics and process monitoring without differential pumping. Measures the residual gases, process contaminates and provides for leak detection.

EQP Series

EQP systems are combined mass and energy analyzers for detailed studies of plasma. EQP systems provide high sensitivity analysis of positive and negative plasma ions neutrals and radicals.

PSM

PSM systems are combined mass and energy analyzers with in- line energy analyser for plasma diagnostics – identifying the key components and reaction kinetics in plasma chemistry.

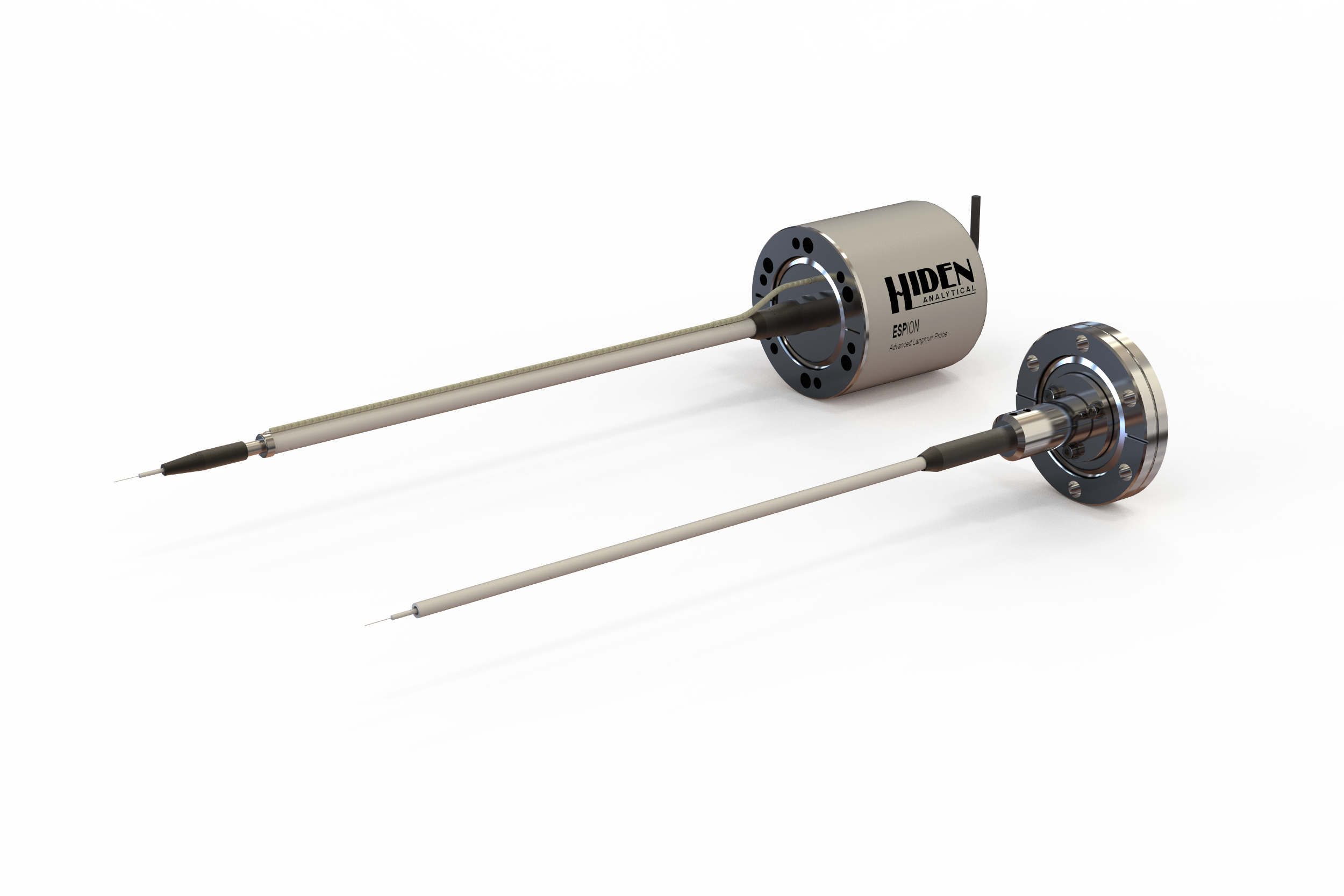

ESPion

An advanced Langmuir probe featuring static and spatially resolved measurements of the primary electrical parameters of low pressure plasma

IMP-EPD

Ion milling probe end point detector for identification of material interfaces in multi-layer device fabrication – applications include magnetic thin films, high temperature superconductors and III-V semiconductors.

XBS

Multiple source deposition monitoring in MBE applications. High contamination resistant purpose designed quadrupole for deposition rate monitoring, source quality analysis and high performance vacuum diagnostics.

TPD Workstation

Integrated UHV temperature programmed desorption workstation. Complete with fast sample load lock, heated sample stage, triple filter quadrupole mass spectrometer and cooled shroud for optimum sensitivity and minimum backgrounds.

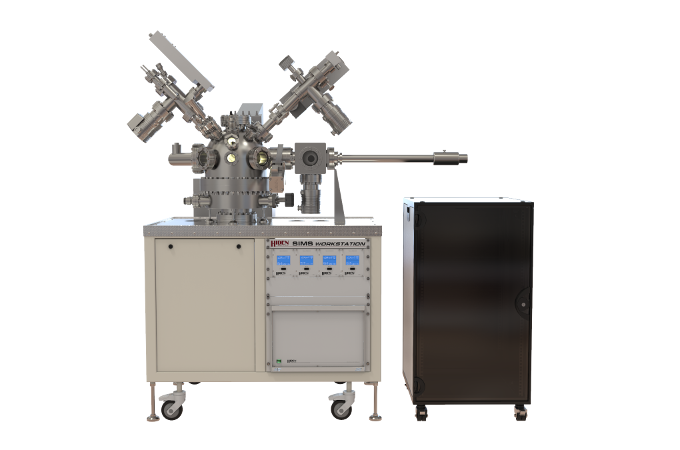

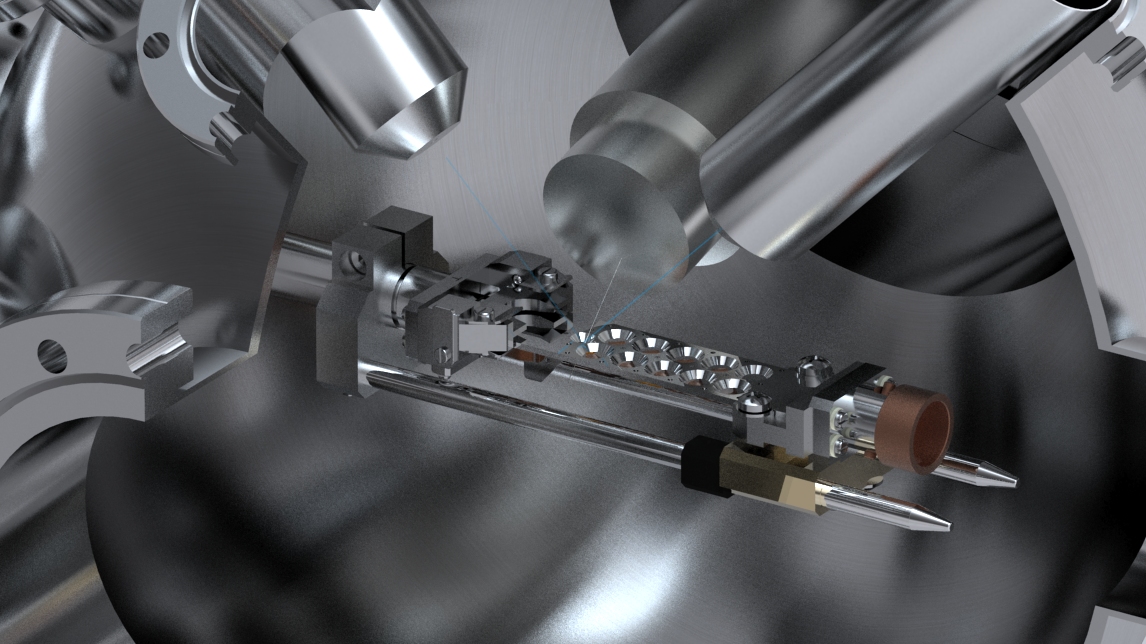

SIMS/SNMS Workstation

The SIMS Workstation combines dynamic and static SIMS analysis with a dual-mode mass spectrometer for positive (+ve) and negative (-ve) ion detection, and an additional secondary neutral mass spectrometry (SNMS) detection mode, for superior flexibility in surface analysis applications.

ToF-qSIMS Workstation

The Hiden TOF-qSIMS system is designed for surface analysis and depth profiling applications of a wide range of materials including polymers, pharmaceuticals, superconductors, semiconductors, alloys, optical and functional coatings and dielectrics, with measurement of trace components to sub-ppm levels.

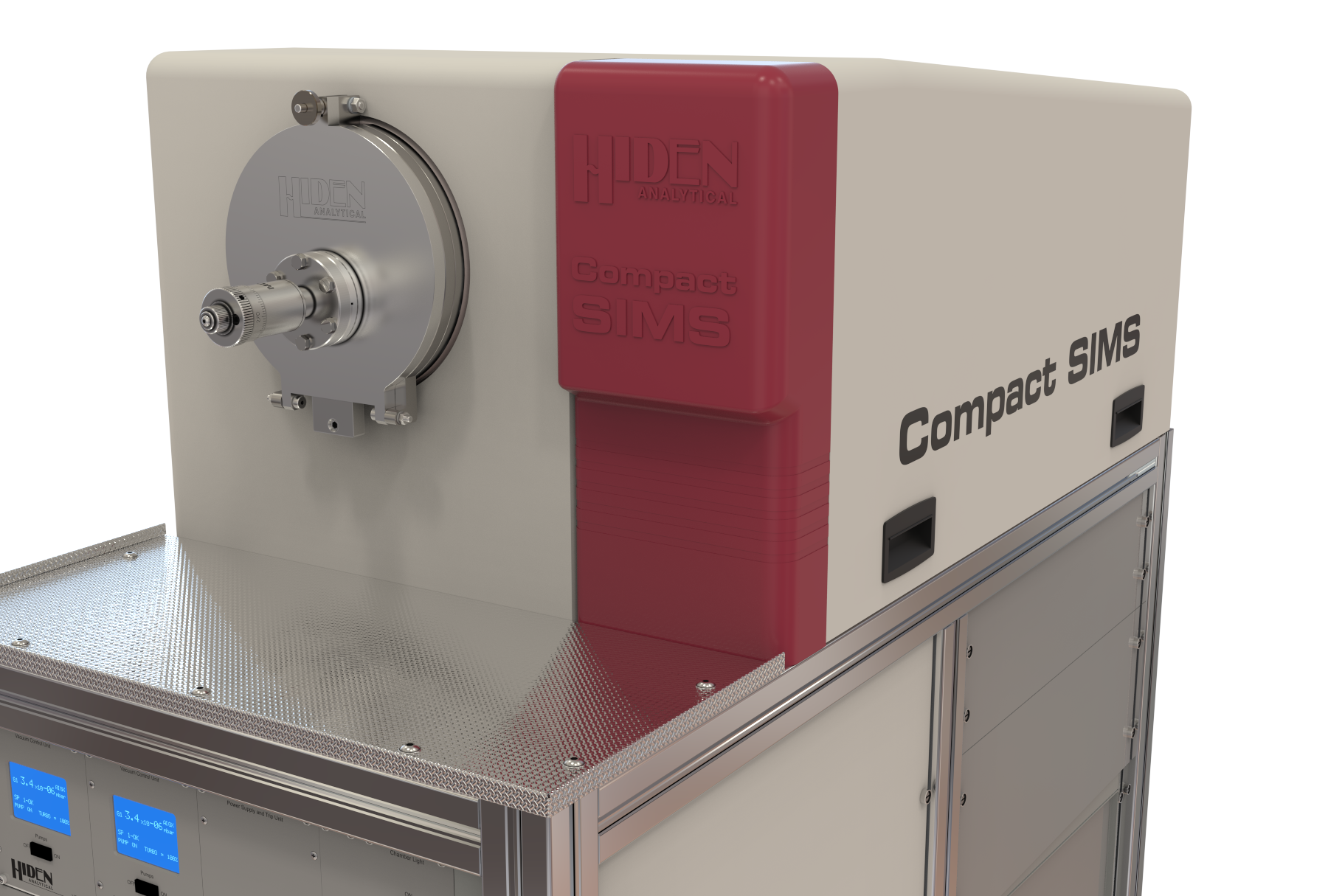

Compact SIMS

The Hiden Compact SIMS (secondary ion mass spectrometry) has a low form factor and simple, user-friendly layout, with outstanding isotopic sensitivity across the entire periodic table.

AutoSIMS

A robust surface analysis solution for high throughput operations, the AutoSIMS can perform hundreds of processes a day without operator intervention.

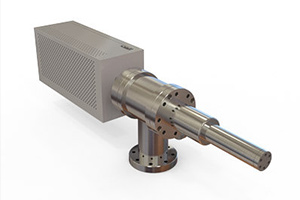

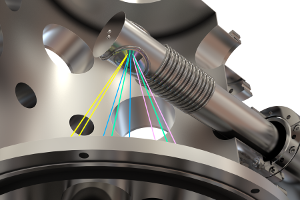

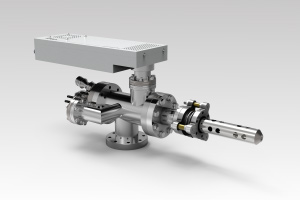

EQS SIMS Analyser

With high transmission rates and an integrated 45° electrostatic sector energy analyser, the Hiden EQS (electrostatic quadrupole) is a versatile positive and negative ion SIMS detector for surface analysis applications at the nanoscale.

MAXIM

The Hiden MAXIM is a complete quadrupole mass spectrometry system with high transmission optics and a triple mass filter, supporting detailed surface composition mapping at a mass range of up to 1000 atomic mass units (AMU).

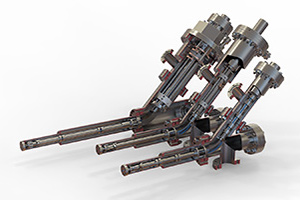

IG5C

The IG5C features a low power, high brightness, surface ionization source coupled to a compact ion column, providing high performance in a small package. The IG5C is designed as a primary ion beam for all SIMS applications, dynamic, static and imaging.

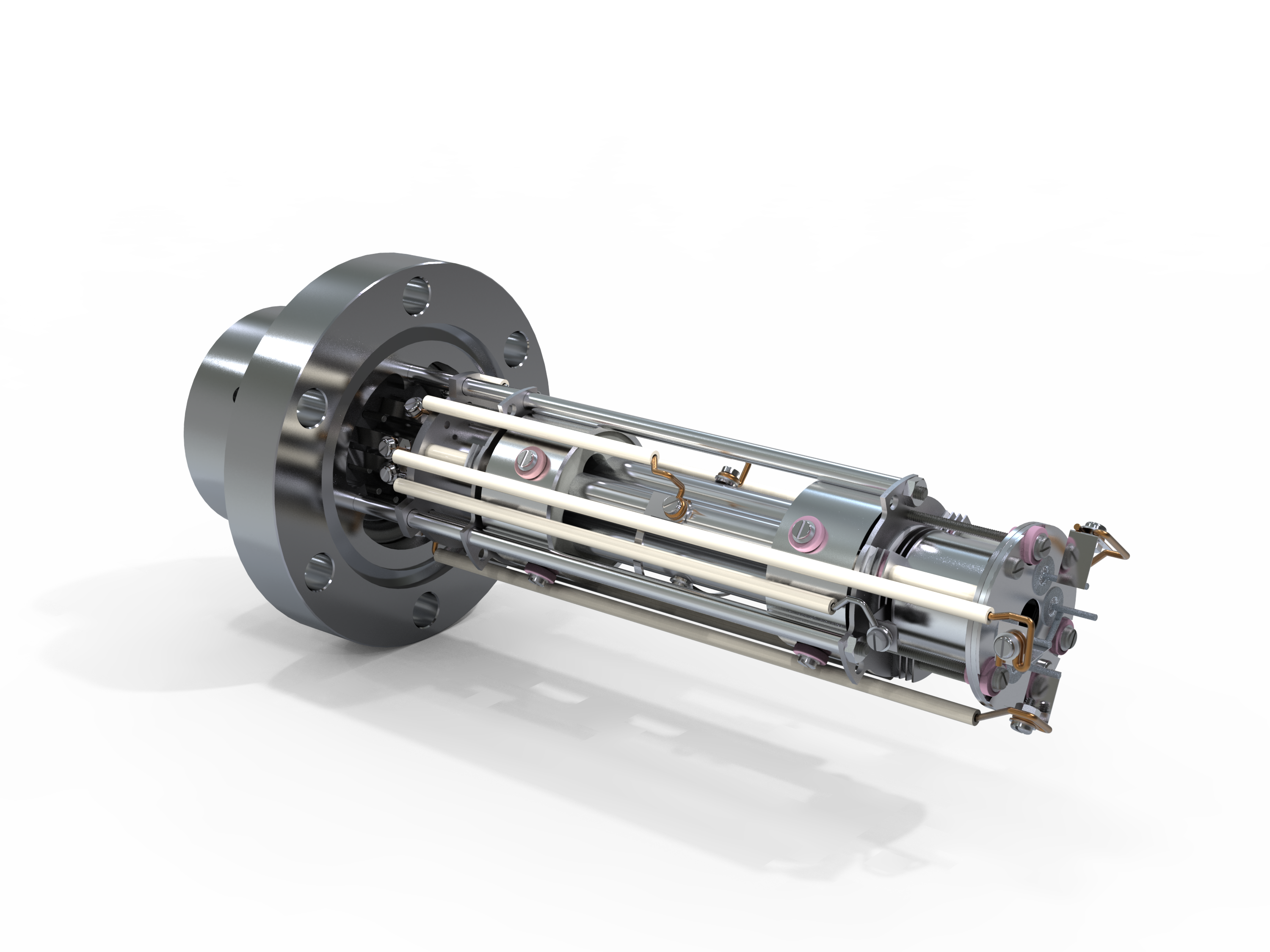

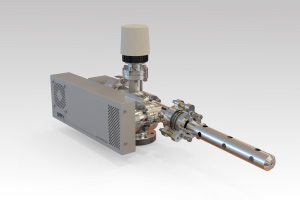

IG20

Designed primarily for oxygen compatibility, the Hiden IG20 is a high-performance electron impact ion source with a high current density for an intense spot of just 100 micrometres (µm) in diameter.