Diamond-Like Carbon (DLC) Coating

Advanced Surface Solutions for High-Performance Applications

Diamond-Like Carbon (DLC) coatings offer exceptional surface properties, including increased hardness, wear resistance, and reduced friction, making them ideal for high-performance applications in the automotive and aerospace industries.

Related Products

Deposition Techniques for DLC Coatings

DLC coatings are typically 2-4 μm thick and are applied using plasma deposition techniques such as Radio Frequency (RF), Capacitively Coupled Plasma (CCP), Expanding Thermal Plasma, and Inductively Coupled Plasma (ICP). By adjusting the plasma chemistry, power, and pressure, the coating properties can be tailored to suit specific applications.

Optimizing DLC Coatings with the Hiden EQP System

The Hiden EQP system allows for direct analysis of plasma species, enabling researchers to understand the conditions required for producing DLC films optimized for specific application requirements. This advanced analytical tool is essential for fine-tuning the deposition process and achieving high-quality, durable coatings.

DLC Coatings from Acetylene-Argon Plasmas

Amorphous carbon coatings can be deposited using RF Capacitively Coupled (CCP) plasma systems, with acetylene (C2H2) as the precursor in an argon plasma. Electron microscopy, AFM, and micro-hardness tests are used to investigate the resulting film properties. The Hiden EQP and ESPion systems determine the plasma composition with variations in gas composition and substrate bias.

Amorphous carbon coatings can be deposited using RF Capacitively Coupled (CCP) plasma systems, with acetylene (C2H2) as the precursor in an argon plasma. Electron microscopy, AFM, and micro-hardness tests are used to investigate the resulting film properties. The Hiden EQP and ESPion systems determine the plasma composition with variations in gas composition and substrate bias.

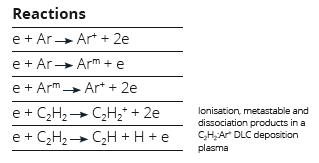

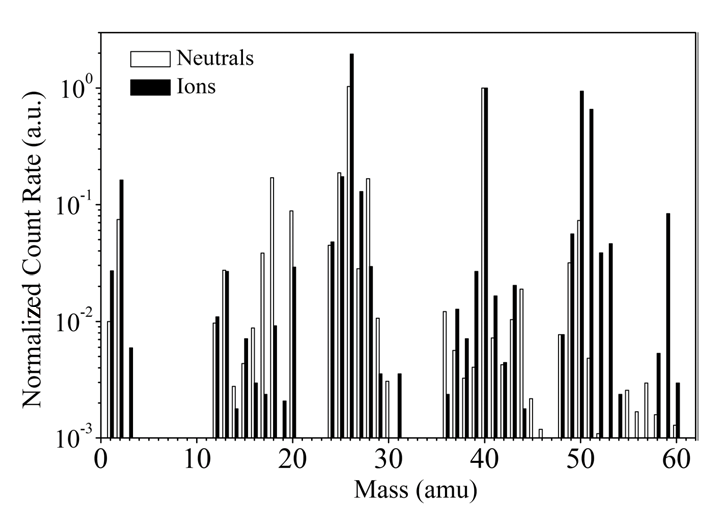

DLC deposition plasmas are rich in acetylene and the C2H radical, with several mechanisms suggested for their production in the plasma. Mass spectra of the ionic and neutral species reveal the presence of C2H, C2H2, C3Hx, C4Hx, and argon species from the plasma gas. With this information, the mechanisms for the nucleation and growth of DLC films can be postulated, and the interdependencies of parameters can be investigated.

Neutral and ion mass spectra normalised with respect to argon in a CCP at 6 mTorr with 2:1 C2H2:Ar ratio

Experience the Advantages of DLC Coatings in High-Performance Applications

DLC coatings offer a wide range of benefits for high-performance applications, from cylinder liners and camshafts in automotive applications to turbine blade coatings and hydraulic actuators in aerospace applications. With the help of advanced plasma deposition techniques and analytical tools like the Hiden EQP system, industries can harness the full potential of DLC coatings to improve the performance and durability of their critical components. For more information on our low pressure plasma and mass spectrometry solutions, contact the Hiden Analytical team today.

Atmospheric Plasma Analysis by Molecular Beam MS – GEC 2004 (1.38 MB)

Atmospheric Pressure Plasma Analysis by Modulated Molecular Beam MS – ICPIG 2005 (256 KB)

Ion Energy Distributions for a DC Plasma – GEC 2003 (250 KB)

Mass Analysis of CF3I Decomposition in a Surface Barrier Discharge – GEC 2011 (2.8 MB)

Mass Spectroscopy of Metastable Species during Plasma Processing – GEC 2011 (2.1 MB)

Time Resolved Ionisation Studies of HIPIMS – PSE 2006 (848 KB)