Plasma Etching and Atomic Layer Etching (ALE)

During plasma processing it is important to maintain the optimum plasma conditions for the process.

Plasma diagnostics are critical in determining and maintaining this process window.

Related Products

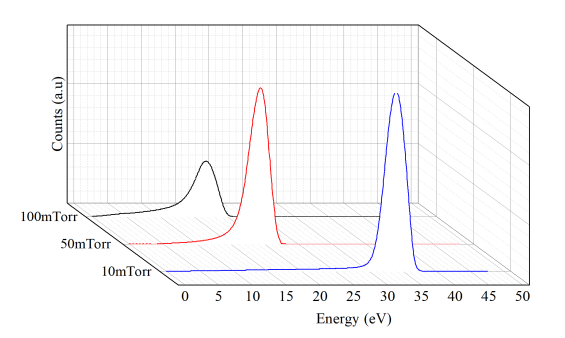

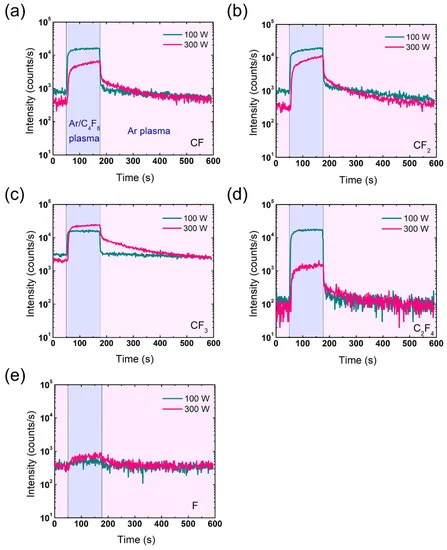

Atomic Layer Etching (ALE) is a two-step process which allows for reliable single atomic layer precision of the etch. The first step is to form a reactive layer on the substrate. The second step then removes this layer, and the underlying substrate layer, in a self-limiting manner. For the second step to be self-limited it is critical that the ion energy is higher than the sputtering threshold of the reactive layer but below that of the substrate layer.

Radical and ion fluxes are also important for the formation of the reactive layer.

The Hiden PSM or EQP can be used to monitor both the fluxes of radicals and ions and their energies in real time.

IEDs as a function of pressure in 1000W Ar.

CF radical densities measured using a QMS during one cycle of ALE at 100W and 300W of (a) CF (b) CF2 (c) CF3; (d) C2F4 and (e) F

Hiden Analytical produces a range of specialized tools for Plasma Etching & ALE. To find out more information about our industry-leading products, get in touch with Hiden Analytical today.

Atmospheric Plasma Analysis by Molecular Beam MS – GEC 2004 (1.38 MB)

Atmospheric Pressure Plasma Analysis by Modulated Molecular Beam MS – ICPIG 2005 (256 KB)

Ion Energy Distributions for a DC Plasma – GEC 2003 (250 KB)

Mass Analysis of CF3I Decomposition in a Surface Barrier Discharge – GEC 2011 (2.8 MB)

Mass Spectroscopy of Metastable Species during Plasma Processing – GEC 2011 (2.1 MB)

Time Resolved Ionisation Studies of HIPIMS – PSE 2006 (848 KB)