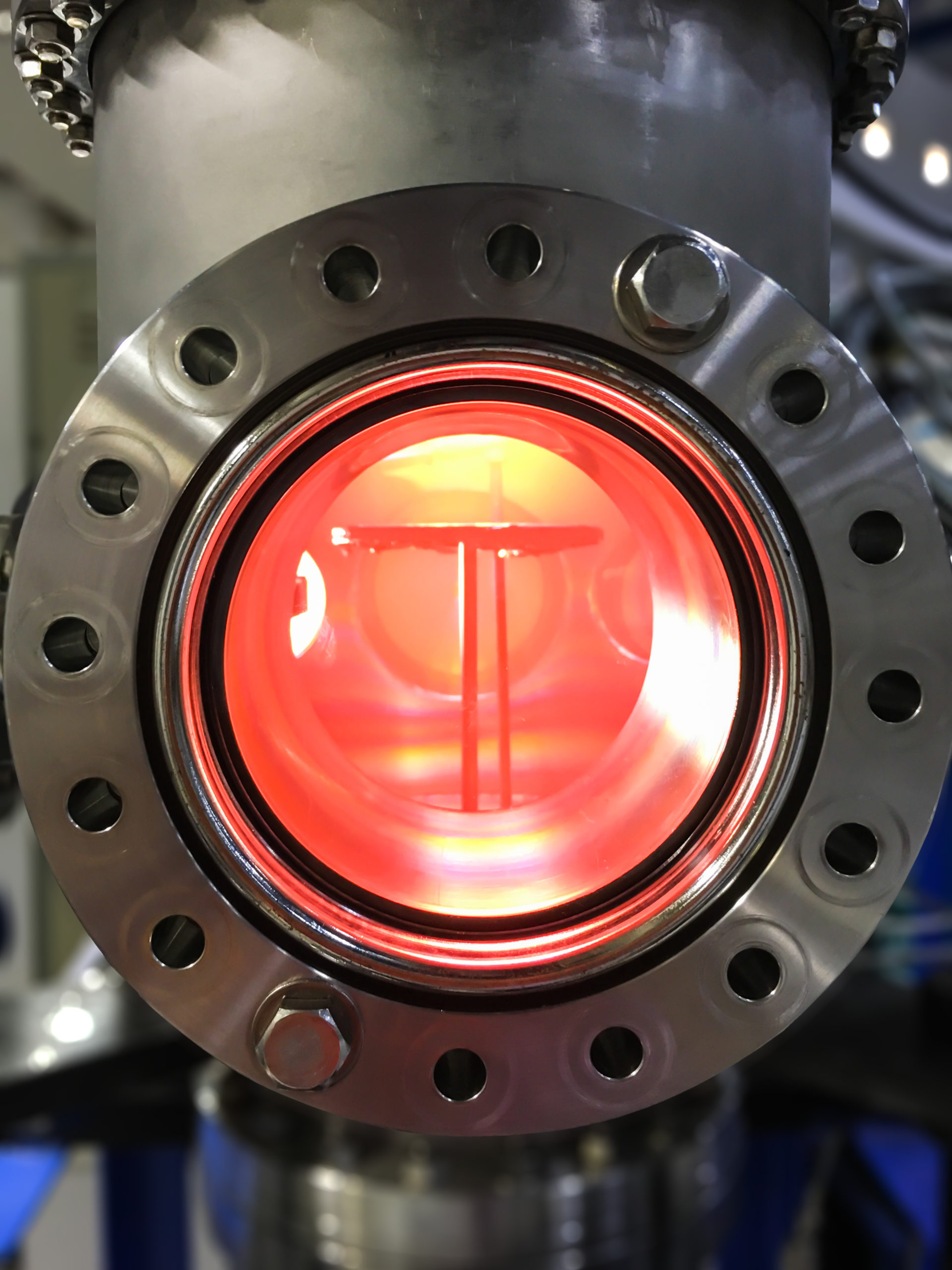

Plasma deposition is a highly versatile advanced manufacturing technique that can be used to deposit layers of a variety of materials over objects of varying sizes and shapes. There are several different methods that fall under the umbrella of plasma deposition, but all of these are based on the same underlying principles.

Plasma deposition methods use the high-energy charged particles that form a plasma to liberate atoms from a target material. The composition of the target material is the desired material to be added to the substrate and the charged particles can be used to erode its surface. As the atoms liberated from the target are neutral in charge, they can escape the strong electromagnetic fields generating in the plasma to collide with the substrate. On collision, the atoms are deposited to form a thin film.

Many metals are compatible with plasma deposition methods, such as aluminum, tantalum, and titanium dioxide, and the finished products created from plasma deposition benefit from excellent physical properties, including outstanding hardness and scratch resistance. A variety of layer thicknesses can be achieved, down to a few nanometers and the process is highly controllable.

Magnetron Sputtering

Magnetron sputtering is a particular type of plasma deposition that uses a magnetic field applied to the target to increase adhesion and deposition rates dramatically. The key advantage of this particular plasma deposition approach is that it does not require melting and evaporation of the source material, making it compatible with the widest range of materials. Magnetron sputtering is often performed under vacuum conditions to minimize the risk of any contamination.

Materials commonly deposited using magnetron sputtering include metals, alloys, and other compounds, and it is compatible with a range of surface types. This includes glasses and other metals and heat-sensitive substrates as the thermal load is minimal and more unusual surfaces such as textiles.

Control over plasma deposition and magnetron sputtering processes requires the use of precise analytical tools. The characteristics of the plasma, including temperature, composition, and density, all influence the deposition process strongly. The elemental composition in the chamber is also important to monitor for contamination and check the desired material composition is correct.

Hiden Analytical Instruments

Hiden Analytical is an expert in quadrupole mass spectrometers that can be used for advanced spectrometric techniques, including monitoring gas and vapor composition during vacuum processing such as sputtering and deposition.3

The Hiden EQP Mass Spectrometer is ideal for plasma analysis during processing and can be used to correlate plasma conditions with the effects in the magnetron deposition process, ensuring you always get the final product and results that you want.

Hiden Analytical’s tools are already proven in magnetron sputtering to enhance the production of silicoboron carbonitride film and for a variation of the method, high power impulse magnetron sputtering to deposit ultra-hard materials like titanium nitride.

To find out more about plasma deposition, read Hiden’s dedicated page here.