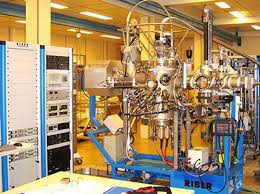

MBE

Systems for Quality Control and Characterisation of MBE Processes

Molecular beam epitaxy takes place in high vacuum or ultra-high vacuum. The most important aspect of MBE is the deposition rate (less than 50 nm/minute) that allows the films to grow epitaxially, that is the growth of a thin layer on the surface of a crystal so that the layer has the same structure as the underlying crystal.

The deposition rates require an ultra high vacuum to achieve the same impurity levels as other deposition techniques.

The absence of carrier gases as well as the ultra high vacuum environment of the MBE technique produces the highest achievable purity of the grown films.

Related Products

The Hiden XBS deposition rate monitor is for molecular beam analysis and provides signal for accurate deposition rate control for growth rates to as low as 1 Angstrom/second.

The Hiden Modular SIMS provides in situ thin film characterisation and contamination control for in situ depth profiling, SIMS imaging and protection of the chamber from contamination.

The Hiden AutoSIMS and TPD Workstation are offered as standalone thin film characterisation tools providing vital information for film quality/production control.