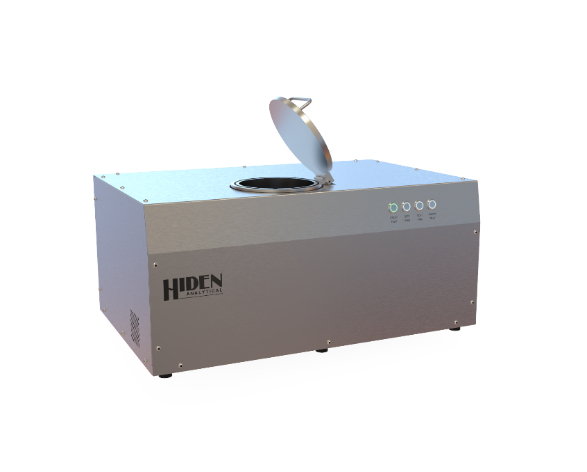

Hiden LAS – Automated High Throughput Leak Analysis System

For further information and pricing, please get in touch with us.

A unique dedicated system for leak analysis of sealed packages.

The Hiden LAS system is designed to analyze the leak rate from sealed packages, from a quality control or research and development perspective.

A variety of fill gases and impurities can be analyzed.

The automated system provides a pass/fail analysis based on the specified leak rate minimum.

Applications

The Hiden Leak Analysis System is automated for simple use in quality control or R&D environments and is designed for analysing the leak tightness of small to medium size sealed packages such as micro gas cylinders and portable battery assemblies.

Using the speed and sensitivity of mass spectrometry, Hiden is able to provide a fast and effective solution for analyzing sealed packages such as Lithium ion batteries and determining leak rates and production quality. A wide range of fill gases, tracer gases or volatile electrolyte species can be analyzed, including typical fill gases such as helium, argon, carbon dioxide and impurities such as water vapour. The system can detect leak rates of less than 1×10-7 mbar.l/s with self-calibration checks against known leak rate standards.

Together with Hiden’s dedicated software, the system is easy to use and provides an automated pass/fail analysis based on the specified leak rate minimum. The software can be customised for the particular application.

The system is supplied with MASsoft Professional Edition software.

The LAS system includes a process template file operating within MASsoft for fully automated operation with start, test, pass , fail indicators. The software records the data automatically. System operation run to run is through push button operation.

This Windows 10 and Windows 11 compatible software allows control of the instrument via USB 2.0, RS232 or Ethernet. The software provides for servicing and supervisor control of the system.