HiPIMS

Enhance Component Performance with Titanium Nitride Deposition using HiPIMS

High Power Impulse Magnetron Sputtering (HiPIMS) is an advanced sputtering technique that enhances the performance and properties of coatings, such as titanium nitride (TiN), by providing increased surface density, reduced friction, and lower substrate temperature. Discover the benefits and applications of HiPIMS for TiN deposition.

Related Products

Understanding HiPIMS: An Advanced Sputtering Technique

HiPIMS, an evolution of conventional magnetron sputtering, offers a unique solution for increasing plasma density and sputtering rates. The technique overcomes the heat generation limitations of traditional methods by applying short, intense pulses to the cathode, with peak power ranging from kW to MW. These pulses generate an extremely dense plasma near the cathode while keeping heat and average operating power low.

Benefits of Titanium Nitride Coatings Using HiPIMS

Titanium nitride (TiN) coatings deposited with HiPIMS technology offer increased hardness and wear resistance over bulk materials. These ultra-hard coatings maintain surface conformity, making them suitable for dimensionally sensitive components such as fasteners, cutting devices, and gears.

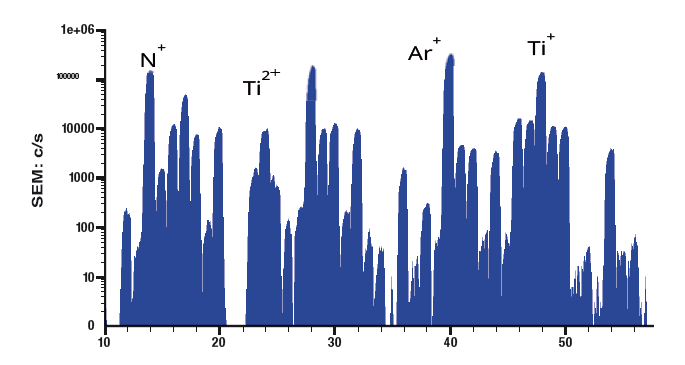

Mass Resolved Ion Spectra: A Comprehensive Plasma Analysis

Utilizing the Hiden EQP mass and energy analyzer system, HiPIMS enables thorough analysis of plasma species in terms of mass and energy. This allows for direct monitoring of the deposition plasma and correlation of changes in parameters such as pressure, gas composition, plasma power, and duty cycle with the resulting film properties. In TiN deposition plasmas, the mass spectral data provides insights into nitrogen, titanium, and argon isotopes and compounds, as well as isotopic and molecular species.

Time averaged mass spectrum from a titanium nitride HiPIMS plasma

Unlocking the Potential of HiPIMS for Advanced Coating Solutions

HiPIMS technology offers a powerful approach for depositing high-quality, wear-resistant titanium nitride coatings. Its ability to control the deposition plasma allows for the fine-tuning of coating properties, ensuring optimal performance in a variety of applications. Explore the potential of HiPIMS for your next advanced coating solution. For more information on our low pressure plasma and mass spectrometry solutions, contact the Hiden Analytical team today.

Atmospheric Plasma Analysis by Molecular Beam MS – GEC 2004 (1.38 MB)

Atmospheric Pressure Plasma Analysis by Modulated Molecular Beam MS – ICPIG 2005 (256 KB)

Ion Energy Distributions for a DC Plasma – GEC 2003 (250 KB)

Mass Analysis of CF3I Decomposition in a Surface Barrier Discharge – GEC 2011 (2.8 MB)

Mass Spectroscopy of Metastable Species during Plasma Processing – GEC 2011 (2.1 MB)

Time Resolved Ionisation Studies of HIPIMS – PSE 2006 (848 KB)

Tailoring the production of Nb superconducting films for SRF cavities: mass/energy spectroscopy and film characterisation 833.39 KB 1 downloads

Tailoring the production of Nb superconducting films for SRF cavities: mass/energy...Comparison on the superconducting properties of Nb and NbTiN thin films produced by both HiPIMS and bipolar HiPIMS 985.15 KB 2 downloads

Comparison on the superconducting properties of Nb and NbTiN thin films produced...Deposition of highly-crystalline AlScN thin films using synchronized HiPIMS – from combinatorial screening to piezoelectric devices 80.00 KB 0 downloads

Deposition of highly-crystalline AlScN thin films using synchronized HiPIMS – from...Novel high-efficiency plasma nitriding process utilizing a high power impulse magnetron sputtering discharge 3.50 MB 9 downloads

Novel high-efficiency plasma nitriding process utilizing a high power impulse magnetron...Deposition of ultrathick heavy-metal alloys on rotating substrates by high-power impulse magnetron sputtering: Target erosion effects 4.39 MB 13 downloads

Deposition of ultrathick heavy-metal alloys on rotating substrates by high-power...Improving the crystallinity and texture of oblique-angle-deposited AlN thin films using reactive synchronized HiPIMS 10.49 MB 13 downloads

Improving the crystallinity and texture of oblique-angle-deposited AlN thin films...Foundations of measurement of electrons, ions and species fluxes toward surfaces in low-temperature plasmas 3.00 MB 21 downloads

Foundations of measurement of electrons, ions and species fluxes toward surfaces...Dense and hard TiWC protective coatings grown with tungsten ion irradiation using WC-HiPIMS/TiC-DCMS co-sputtering technique without external heating 4.12 MB 17 downloads

Dense and hard TiWC protective coatings grown with tungsten ion irradiation using...Improving the crystallinity and texture of oblique-angle-deposited AlN thin films using reactive synchronized HiPIMS 4.30 MB 14 downloads

Improving the crystallinity and texture of oblique-angle-deposited AlN thin films...Ion energy analysis of a bipolar HiPIMS discharge using a retarding field energy analyser 1.20 MB 25 downloads

Ion energy analysis of a bipolar HiPIMS discharge using a retarding field energy...- 1

- 2