Thin films are prevalent in a range of technological applications, from packing materials to medical devices. Because of the unique properties of these films, they have significantly enhanced many industries and opened doors to innovative solutions. However, for thin films to perform optimally, the issue of contaminants must first be addressed.

Contaminant analysis, which involves detecting and analysing contaminants at trace levels, is of paramount importance in thin film engineering. By understanding the importance of contaminant analysis, scientists and engineers can develop strategies to mitigate the negative effects of contaminants, optimise manufacturing processes, and enhance the quality and reliability of thin films.

What are the Properties of Thin Films?

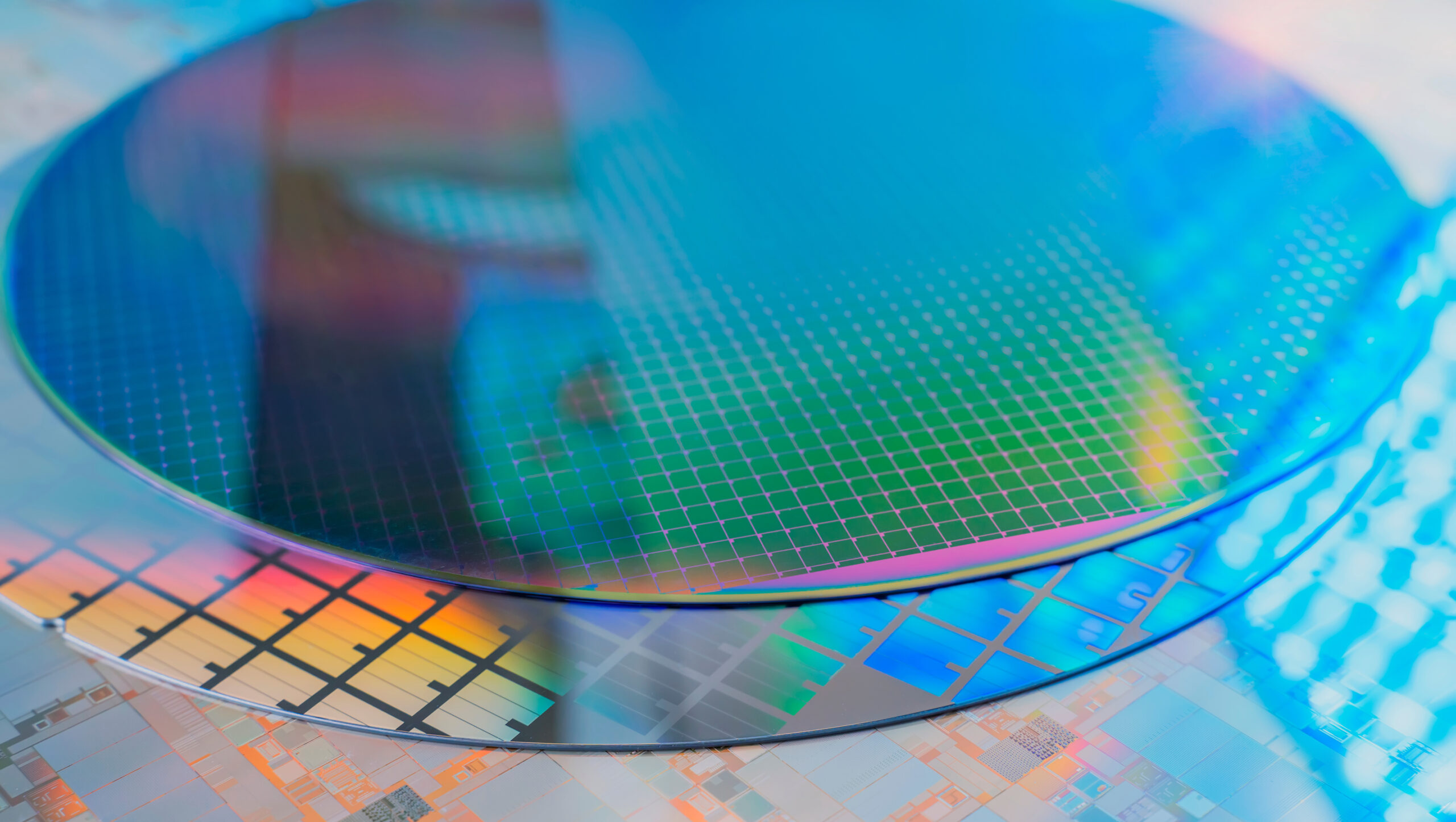

Thin films are characterised by their nanoscale thickness, typically ranging from a few nanometers to several micrometres. Despite their minuscule size, thin films exhibit unique properties that make them invaluable in technological applications. These properties include mechanical strength, electrical conductivity, optical transparency, and chemical stability. However, even at such small dimensions, any contaminants can heavily impact the performance and reliability of thin films.

Many substances can be classified as contaminants, including organic contaminants, particulate matter, and impurities from the manufacturing process. These contaminants may not be obvious or even visible at trace levels but can have detrimental effects on the film’s properties. For instance, organic contaminants can interfere with the electrical conductivity of thin films, leading to reduced performance and reliability. Therefore, the detection and analysis of contaminants in thin films are essential for ensuring their optimal properties and functionality.

Contaminant Analysis Techniques

Contaminant analysis in thin film engineering relies on various analytical methods to identify and characterise contaminants accurately. These methods employ different instruments and techniques, such as gas analysers, mass spectrometry, and surface analysis. The primary aim is to detect contaminants quickly and efficiently, enabling engineers to identify their sources and take appropriate measures to reduce their impact.

One common method of analysing contaminants is membrane inlet mass spectroscopy (MIMS). It is a highly effective solution that has the ability to analyse at sub-ppb levels and detect low concentration levels. MIMS is particularly suited for detecting and characterising contaminants in various applications.

Contaminant Film Thickness

In addition to identifying contaminants, analysing the thickness of the contaminant film is essential for understanding its impact on the properties of thin films. The presence of contaminants increases friction and can lead to wear and failure of the thin film in practical applications, which could have detrimental effects.

By studying the thickness of the contaminant film, scientists can optimise the manufacturing process to minimise the presence of contaminants and enhance the performance of thin films. Controlling the thickness of the contaminant film is particularly crucial in applications where low friction and wear resistance are paramount.

Contaminant Analysis with Hiden Analytical

Contaminant analysis is a vital aspect of thin film engineering, ensuring the quality, performance, and reliability of thin films in various technological applications. Through the use of advanced analytical methods, such as SIMS and SNMS, scientists can detect and identify contaminants on the surface layers of a sample, enabling them to take corrective actions and optimise manufacturing processes.

Hiden Analytical has developed a range of products that are suitable for contaminant analysis, with one example being the SIMS Workstation. It is the ideal solution for analysing the upper layers of samples in thin film engineering processes and can be modified to meet user requirements. The Hiden SIMS Workstation includes various features such as differentially pumped primary excitation sources, ion gun raster control for depth profiling, electron flood gun for insulator studies, and options for vacuum chamber bakeout heaters. It also offers fast sample transfer, UHV manipulator for precise sample positioning, SIMS elemental imaging, and automatic tuning and alignment capabilities for optimal performance.

To learn more about the products we offer for contaminant analysis, contact us today.

Alternatively, if you’re interested in other contaminant analysis techniques, you can read one of our previous blog posts here.