A residual gas analyser (RGA) is a crucial piece of equipment known as a mass spectrometer used in many industries to conduct high-sensitivity, real-time analysis. Gas analysers allow analysts to maintain a high level of quality control and gas monitoring by identifying the composition and quality of residual gases and vapour species. This post will examine why residual gas analysis is used in semiconductor production.

Semiconductor Production

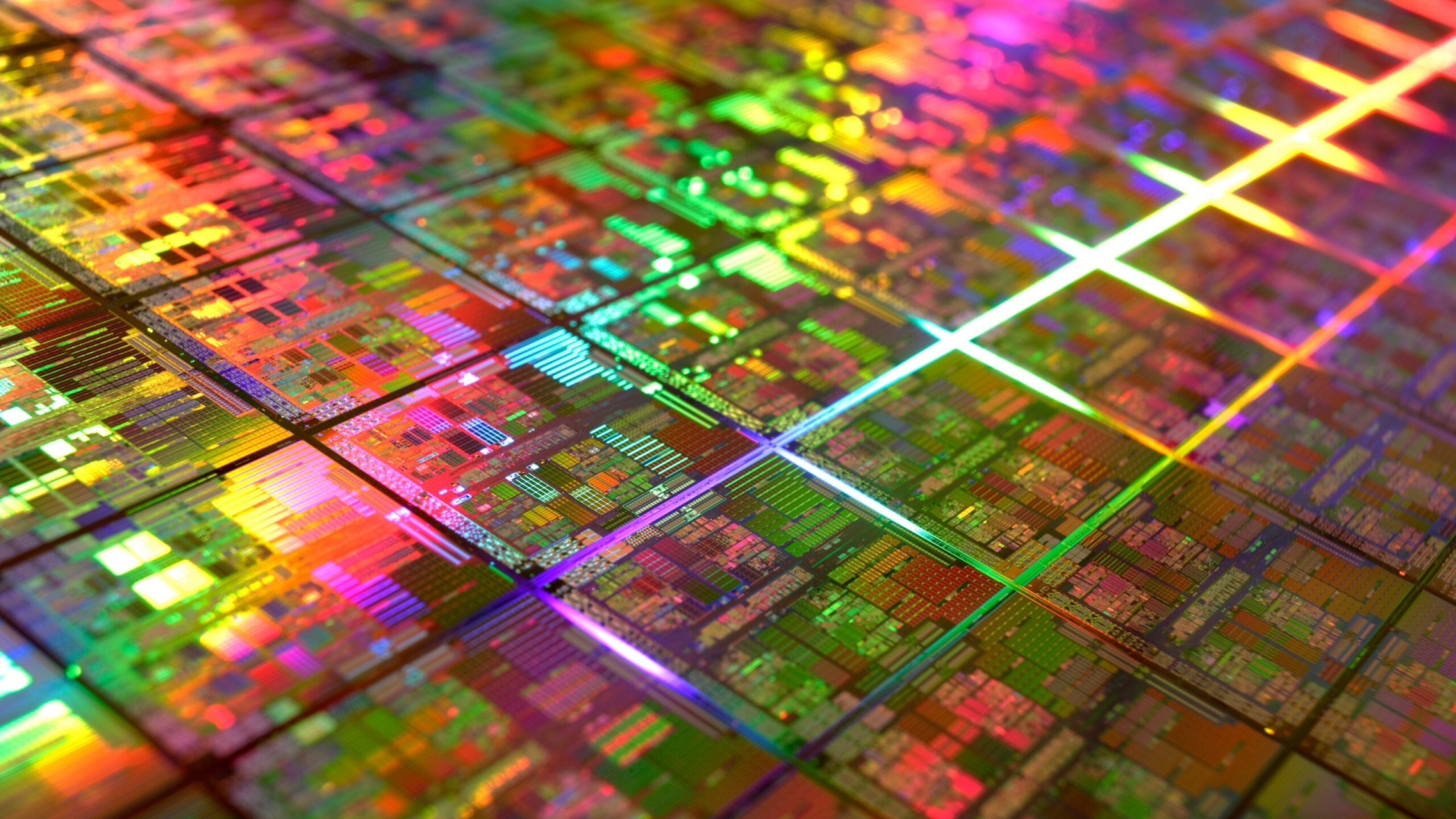

Semiconductors are vital for digital products that help us communicate with people around the world. These are commonly used to make electronic chips, which are used in computer components and other electronic devices such as medical devices, smartphones and applications for the Internet of Things (IoT). However, as the demand for better technology grows, the need for high-quality semiconductors will also increase, and their processes will need to become more streamlined.

Gases are used throughout the many stages of the semiconductor manufacturing process chain, and the right chemicals and high-purity gases must be available. Gases are used from the first stages of production to the final coating and even cleaning processes, highlighting how key they are to the semiconductor industry.

Because gases are critical to the processes, it is equally essential to ensure that the gases used are of the highest quality and that contamination is prevented. Residual gas analysis can support the quality control and monitoring required in the semiconductor industry.

Why is Residual Gas Analysis (RGA) Used?

Residual gas analysis is a term used to describe the processes of analysing gas and vapour species in vacuum chambers. Analysing gases and vapours can be carried out accurately and quickly with a mass spectrometer for many applications such as leak detection, gas composition measurement studies and quality control.

Aside from identifying and monitoring gases for quality control purposes, RGA provides several other benefits, such as:

- Increased productivity

- Increased throughput

- Monitor maintenance requirements

- Reduced costs

- Reduced unplanned downtime

The gases used in the semiconductor industry can have harmful effects, and even a minor discrepancy can lead to contamination and damage throughout the production process. Being able to detect a gas leak or promptly identify contaminants will help keep personnel and the environment safe and maintain the production process.

Hiden Analytical and Residual Gas Analysis

Hiden Analytical develop and manufacture a wide range of products suitable for residual gas analysis in several industries. Our mass spectrometers provide outstanding adaptability to support the detection of contaminants and quality issues with gas streams.

Our quantitative gas analyser (QGA) is a system used for the continuous analysis of multiple gases and vapours, which offers fast response times and has a detection capability of 100 parts per billion. Depending on your requirements, we also have systems to support less demanding and more advanced applications.

If you’re ready to make a purchase or want more information on our residual gas analysers, contact a member of our team today.