Gas analysis is used in vacuum processing applications to identify the composition and quality of residual gases and vapour species. Measurements are carried out to ensure strict quality control in vacuum processing and to monitor gases, supporting the enhancement of process yields and product quality. In this blog post, we will outline why it is necessary to use gas analysis in vacuum processing.

What is Gas Analysis?

Gas analysis is commonly referred to as residual gas analysis, which covers analysing gas and vapour species in vacuum environments. This is a necessary step to determine the quality of the vacuum and to detect any impurities in the process chamber.

Applications of Gas Analysis

In vacuum processing, gas analysis is commonly used for detecting contaminants and leaks, reaction monitoring and quality control (QA/QC), although this is not an exhaustive list. Gas analysers are typically installed into the vacuum chamber to promptly detect even minuscule impurities in the environment and thus help monitor the quality of the vacuum. The instruments are also used to monitor any changes in the vacuum environment as well as gas-phase reactions.

The Importance of Gas Analysis in Vacuum Processing

As a result of the processes in a vacuum chamber, gas analysis can be critical for keeping both personnel and the environment safe. The outgassing of deleterious compounds and reaction products from some materials can damage electronic equipment and components; therefore, ensuring the released gases are within specific parameters is necessary.

Streamlining the Process

Aside from keeping people safe, gas analysis in vacuum processing is also used to streamline the process. This is made possible by quickly and effectively detecting any dangers or impurities in the vacuum chambers and surrounding environment, allowing analysts to manage any issues promptly.

Monitor Persistent Species

Gas analysers are frequently used at partial pressures to monitor species such as hydrocarbons, volatile organic compounds (VOCs) and water which are persistent and might not always be cleared from the chamber after processing. Additionally, the analysers can be programmed to search for specific gases, either leaking or remaining in the chamber, which the analyst can set.

The Benefits of Gas Analysers

Gas analysers are used to quickly identify process managers of any problems in the vacuum systems. The benefits of this are vital for streamlining processes and include the following:

- Increase productivity

- Increase product yield

- Increase throughput

- Maintain electronic components

- Reduce costs

- Reduce downtime

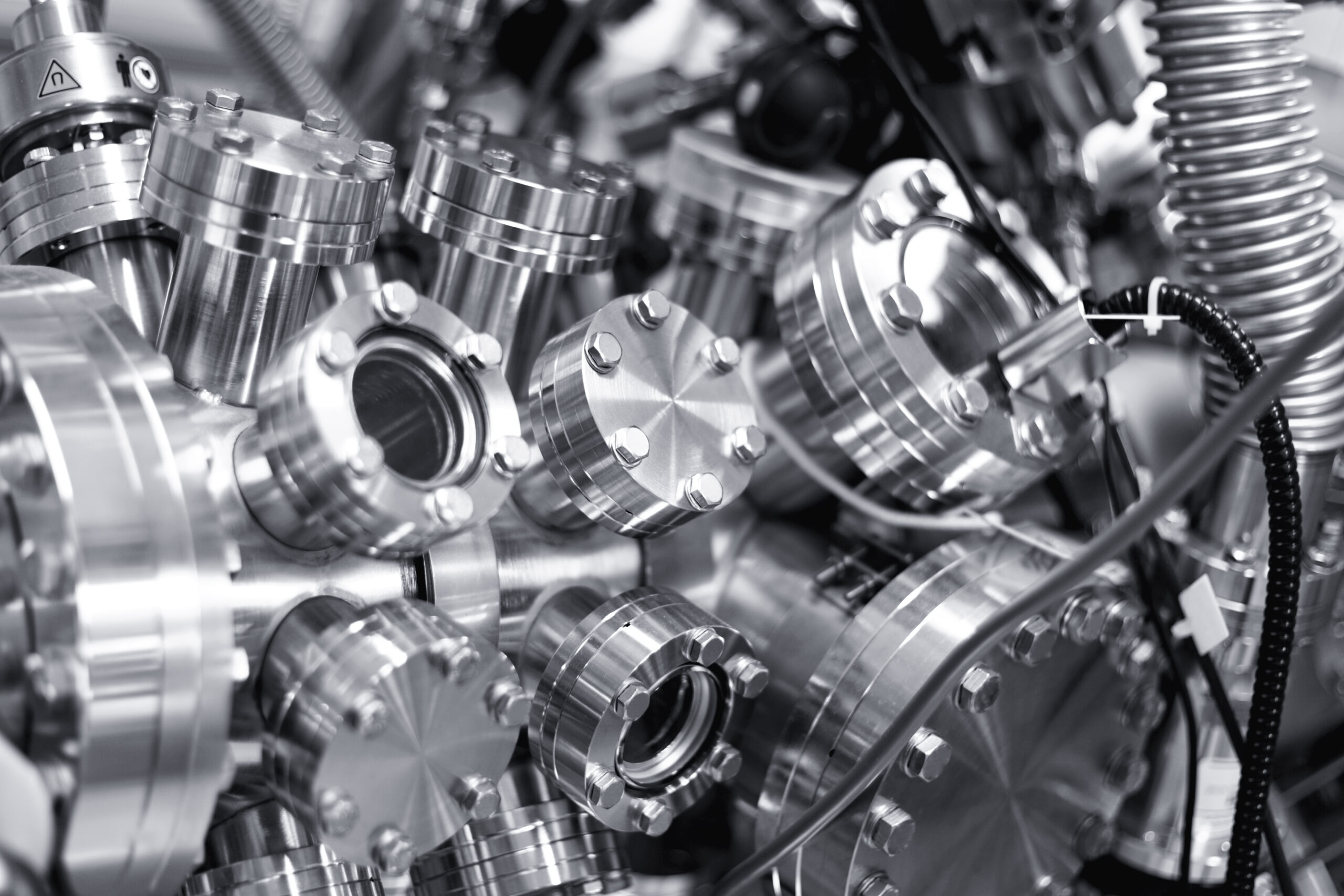

Hiden Analytical: Gas Analysis and Vacuum Process Monitoring

A range of residual gas analysers available through Hiden Analytical are ideal solutions for leak detection and vacuum diagnostics. We manufacture gas analysis solutions for a worldwide base of customers and their precision applications, including several compact gas analysers, including our benchtop HPR-30 series systems, which are suitable for rapid gas analysis in vacuum processing applications.

For more information on our gas analysers, please don’t hesitate to contact us today.