Wastewater and Sludge Analysis

Thermal and Thermo-Chemical Pre-treatment of Waste Residue

Discover innovative wastewater and sludge analysis techniques, including thermal and thermo-chemical pre-treatment methods, that boost biogas production and contribute to a more sustainable future.

Related Products

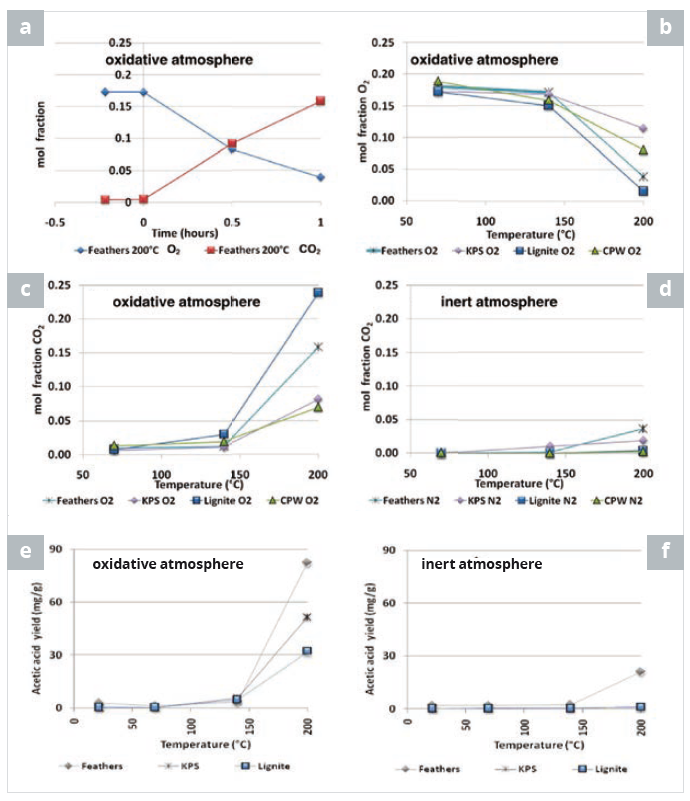

Our state-of-the-art HPR-40 DSA Membrane Inlet Mass Spectrometer (MIMS) technique allows you to monitor changes in volatile components during pre-treatment. In Figure 11, MIMS was utilized to track oxygen consumption and carbon dioxide production during the thermal pre-treatment process for four different substrates: coal, Kraft pulp solids, chicken feathers, and chicken processing waste. The graphs display variations in O2 and CO2 at 200°C (a), total O2 consumption (b), total CO2 production in oxidative (c) and inert atmospheres (d).

Furthermore, the research group observed the production of acetic acid in both oxidative (e) and inert (f) atmospheres. Importantly, the methane yield increased after pre-treatment at 140°C but decreased at a higher temperature (200°C).

Discover innovative wastewater and sludge analysis techniques, including thermal and thermo-chemical pre-treatment methods, that boost biogas production and contribute to a more sustainable future.

Figure 11 (a-f): Changes in O2 and CO2 when feathers are treated at 200˚C (a), total O2 consumption (b) and total CO2 production for all substances after 1h under oxidative atmosphere (c) and inert atmosphere (d) at various temperature. Acetic acid production under an oxidative (e) and inert atmosphere (f) up to 200˚C.

Sampling Inlets for Hiden Mass Spectrometers: Gas, Vapour and Liquid Sampling Systems

Solutions for Dissolved Gas Analysis in Swimming Pools

Membrane Inlet Mass Spectrometry (MIMS)

pQA – Portable MIMS Quadrupole Analyser