Plasma discharges are widely used in technical processes such as surface modification and thin-film deposition and etching. In this sense, the corresponding quantitative characterization of plasma sources is a topic of particular importance for a fundamental understanding of plasma sources as well as for a technological optimization of processes. Hydrogen plasmas play a certain role in technical discharges so that a precise determination of the absolute hydrogen fluxes to a plasma-treated surface is very desirable. This is important for understanding both the discharge mechanism and the plasma-induced processes at the surface.

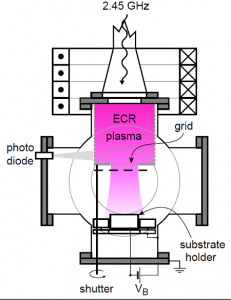

A custom built electron-cyclotron-resonance (ECR) plasma source with a biased sample holder was thoroughly characterized with respect to the deuterium fluxes impinging on the substrate holder. The mass distribution of the impinging ions was measured with a HIDEN plasma monitor (Model HIDEN EQP 300). The plasma monitor was inserted in a mock-up sample holder thus allowing the measurement of the flux arriving at the usual sample position. In order to shield the plasma monitor from the magnetic field necessary for the ECR discharge, the mock-up sample holder was constructed from soft iron. An additional soft iron shielding cylinder was placed around the ion optics of the plasma monitor. The plasma monitor is differentially pumped in order to maintain a pressure of about 10−7 to 10−6 Pa during operation. The aperture in the mock-up sample holder was 10μm. For absolute quantification of the mass-integrated ion flux to the sample holder a retarding field analyser (RFA) was used.

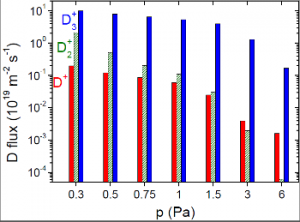

Figure 1: Ion-species-resolved deuteron flux as a function of the D2 gas pressure, measured at a constant microwave input power of 144 W and with the sample holder at floating potential

The resulting ion fluxes impinging on the substrate holder for a microwave power of 144 W are presented in Fig. 1 as a function of operating pressure in the range from 0.3 to 6 Pa. Even at the lowest investigated pressure of 0.3 Pa the dominating ion species hitting the sample surface is D3+. The dominant production pathway for this ion is an ion-molecule reaction in the bulk plasma. A D2+ ion collides with a D2 molecule producing a D3+ and a D atom. With increasing pressure the probability for this reaction increases so that the relative ion species composition changes. With increasing pressure more and more D3+ ions are produced at the expense of the primary D2+ ion which is produced in the bulk plasma by electron-induced ionization of D2 molecules. At pressures higher than about 1.5 Pa the total target current decreases due to a decrease of the plasma density, but still the relative contribution of D3+continues to increase. At the highest investigated pressure of 6 Pa the contribution of D2+ is almost negligible (less than 10-3). In contrast to D2+ the fraction of D+ does not significantly change. D+ is, as D2+, produced by electron-induced ionization of D2 molecules and additionally by direct ionisation of atomic D (D plasma concentration is about 1 %), but in contrast, the cross section for an ion molecule reaction of D+ is much lower than that of D2+.

For the defined standard operating parameters of our plasma source, i.e. a D2 plasma at p = 1.0 Pa, PMW = 144 W and the sample holder at floating potential, the total deuteron flux in the form of ions is 5.6×1019 Dm−2. This corresponds to a total ion flux of 1.9×1019 ions m−2. 94% of these ions are D+3, 3% are D+2, and 3% are D+ ions. The ion flux increases monotonically by about a factor of 2 if the DC bias voltage is increased to −600 V.

Experimental setup:

Figure 2: Schematic view of the experimental set-up. To quantify the particle flux to the substrate the substrate holder is replaced by a mock-up containing the EQP plasma monitor (not shown)

Paper Reference:

P. Wang, W. Jacob, M. Balden, A. Manhard, T. Schwarz-Selinger (2012) “Erosion of tungsten-doped amorphous carbon films in oxygen plasma” Journal of Nuclear Materials 420 (1-3), 101-109

Hiden Product: EQP Mass & Energy Analyser for Plasma Diagnostics

Read Full Article: Customer Research Review Issue 1120/09 Thin Films, Plasma and Surface Engineering