Our research project concerns the H2S purification from a biogas stream by direct and selective oxidation to sulphur and water at low temperature.

Our research project concerns the H2S purification from a biogas stream by direct and selective oxidation to sulphur and water at low temperature.

Biogas is a renewable energy source that can be produced from biomass, agricultural and industrial waste and sewage sludge. Its main components are CH4, CO2 but unfortunately sulphur based compounds such as H2S, COS are also present.

The main limitation of the biogas utilization as fuel in Molten Carbonate Fuel Cells is due to the presence of sulphur compounds such as H2S that can poison the main components of the fuel cell.

The partial H2S oxidation reaction is carried out in presence of vanadium-based catalysts that are active and very selective toward Sulphur formation.

The aim of the work is to study the preparation procedure of V2O5/CeO2 structured catalysts from the washcoating with CeO2–ZrO2 to the deposition of the active phase (V2O5) for the abatement of H2S at 150–200°C.

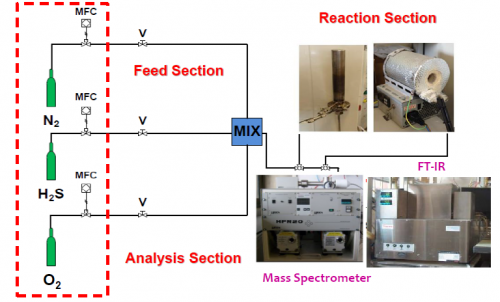

The catalytic tests were carried out in a fixed bed flow reactor, made of a steel tube 21 cm long and a 14 mm of internal diameter. The reactor is inserted in an electrical furnace equipped with a PID electronic temperature controller. A thermocouple is inserted in a steel sheath concentric to the reactor. The catalytic tests were carried out in the temperature range 150– 250 °C, with a GHSV of 180,000 h-1, by feeding 500 ppm of H2S, 250 ppm of O2 and N2 to balance.

In Figure 1, the scheme of the laboratory plant is shown.

The exhaust stream (H2S, O2, H2O) was analyzed by a quadruple filter mass spectrometer (Hiden HPR-20 QIC R&D). It was equipped with a sulphur trap to prevent that the sulphur causes the occlusion of the capillary and damage to the fundamental parts of the analyzer. The concentration of SO2, which may be present at a very low concentration in the stream leaving the reactor is also monitored by an analyzer FT-IR Multi-gas continually.

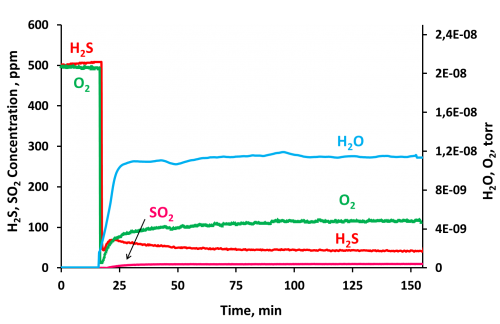

In Figure 2 we have shown the typical behaviour of a catalytic activity test carried out by using a catalyst with the highest vanadium loading (19 wt%V2O5).

It is worth noting that when the feed stream is sent to the reactor, an immediate and strong decrease of the H2S concentration and O2 signal is verified, while a very low SO2 concentration (10 ppm) is produced. The formation of the water, that remains stable and constant during the test, is indicated by the signal m/z = 18. During this test (2h), no deactivation phenomena were observed. The final H2S conversion value was higher than 90%.

Finally, the structured catalysts can be considered, based on these results, promising and innovative catalytic systems for the H2S partial oxidation at low temperatures, having shown good catalytic performances with results very similar to those showed by powder catalysts.

Project summary by:

Vincenzo Palma and Daniela Barba

Department of Industrial Engineering

University of Salerno

Via Giovanni Paolo II

132, Fisciano, SA, Italy

Paper Reference: V. Palma & D. Barba (2014) “H2S purification from biogas by direct selective oxidation to sulphur on V2O5–CeO2 structured catalysts” Fuel 135, 99-104