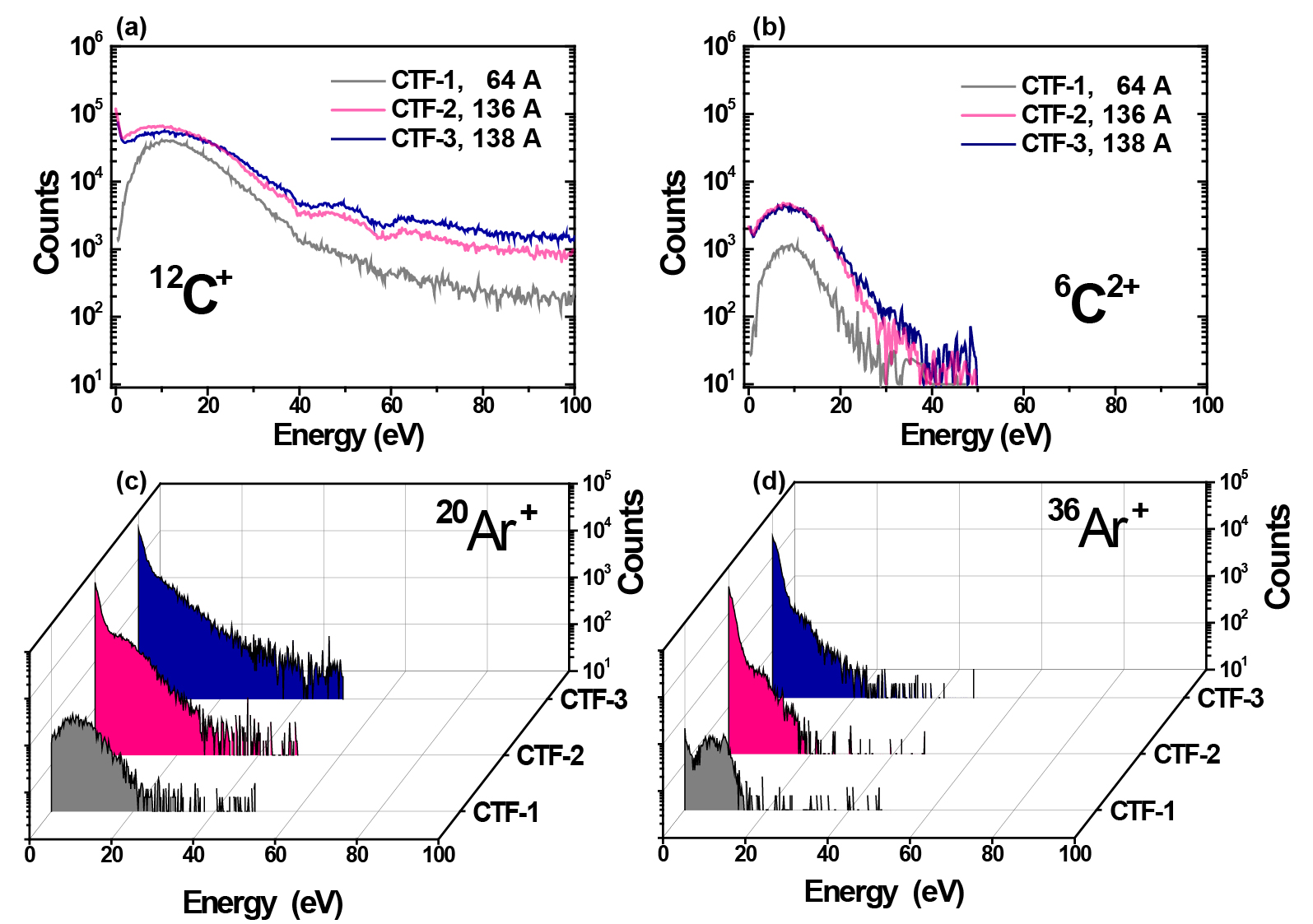

Obtaining carbon films deposited by physical vapor deposition that improve the mechanical and tribological properties of a film-substrate system depends on the energetic levels and the number of the ion species in the plasma of the deposition process. An effective way to measure both plasma properties is with a quadrupole mass spectrometer detector from Hiden Analytical. Thanks to this detector we could obtain time-average ion energy distribution function (IEDF) of the carbon ion (C+), doubly ionized carbon (C2+), argon (Ar+), and doubly ionized argon (Ar2+) ions in the discharge plasma, from mimic tests of the deposition process (see Fig. 1). This data allows us to estimate the carbon ion energy with which they reach the surface of the carbon film in formation. Therefore, we can semi-quantify according with the energetic level of the carbon ions the sp3 and sp2 bonding that could have formed during the deposition process. This is supported with Raman spectroscopy and through the mechanical properties measurements for the case of our workgroup. In our last investigation titled: “Influence of plasma ionization on the elastic modulus and tribology behavior of carbon films deposited by the HiPIMS technique” [1], we found interesting plasma characterization results. We found that the ion energy distribution function results showed that the ionization and high-energy tail (showed in the IEDF graphs, see Fig. 1) increased with discharge current and showed carbon-ion energies above 100 eV. Furthermore, the thickness of the carbon films seems to be attributed to the target voltage used, which is correlated with the number of carbon ions in the deposition process obtained with the quadrupole mass spectrometer detector.

Figure 1. Time-averaged IEDFs for (a) C+, (b) C2+, (c) Ar+, and (d) Ar2+ ions compared with the three Ipk used (64, 136, and 138 A). The formats of the graphs (c) and (d) were changed for better visualization. Obtained from [1].

The bonding properties obtained by Raman spectroscopy revealed higher levels of sp3 bonding for the sample with the lowest discharge current used; this can be corroborated with its highest elastic modulus (132 GPa) obtained from atomic force acoustic microscopy (AFAM). This increment in the sp3 bonding in comparison to others two sample with higher discharge current values was attributed to the lower number of less energetic carbon ions that over- come the 100-eV limit. Therefore, the more this limit is exceeded, the greater is the drop in sp3 bonding and the elastic modulus decreases. The AFM topography showed significant changes in the microstructure of the most ion energetic film, which was attributed to a columnar rearrangement during the deposition process. In addition, such rearrangement suggested that the drop in sp3 bonding with ion energy was temporally stopped or slowed down. The nanofrictional forces were mainly affected by the changes in the surface microstructure, obtaining lower friction coefficients for the surface microstructures with lower roughness values and less orientated grain growth. The macrotribology tests have shown lower friction coefficients for the carbon films with a higher number of carbon ions above 100 eV. This reduced the sp3 bonding in these films, generating easier or less energetic sp3 → sp2 transformations, producing easier graphitization, which significantly reduced the friction coefficient. These results motived us to start several new several new investigations related with the influence of number of ions and ion-energy of the plasma on the thin films and hard coatings with different compositions and configurations.

Project summary by: Dr. César D. Rivera Tello, Departamento de Ingeniería Mecánica Eléctrica, CUCEI, Universidad de Guadalajara, Blvd. Marcelino García Barragán 1421, Olímpica, Guadalajara, Jalisco C.P., 44430, Mexico

Paper Reference: C. D Rivera-Tello, F. J. Flores-Ruiz, M. Flores-Jiménez, and M. Flores, “Influence of plasma ionization on the elastic modulus and tribology behavior of carbon films deposited by the HiPIMS technique,” Ceram. Int., vol. 49, no. June 2022, pp. 2427–2439, 2022, doi: 10.1016/j.ceramint.2022.09.216.

Hiden Product: EQP

Download PDF: AP-EQP-202151_Mexico

To find out more about these products visit the EQP product page or if you would like to contact us directly please Send us a Message.