Tin oxide (SnO2) has been widely explored for applications such as transparent electrodes, n-type thin-film transistor (TFT) solar cells, electromagnetic shielding, and gas sensors due to its excellent semiconductor properties, low resistance, and high optical transparency in the visible range. However, few studies on the preparation of SnO2 films using high-power pulsed magnetron sputtering have been reported. The high-power pulsed magnetron sputtering (HiPIMS) technology developed based on conventional magnetron sputtering has attracted people’s attention due to its extremely high target ionization rate. It works by increasing the peak power of the pulses. A magnetron sputtering technique achieves a high sputtering metal ionization rate while maintaining a low pulse duty cycle. By applying power in pulses with a high amplitude and a low duty cycle, large fractions of sputtered atoms and near-target gases can be ionized. The dense plasma in front of the target serves a dual purpose of maintaining the discharge and assisting film growth by altering the microstructure of growing films. Oxygen content is a critical parameter in the fabrication of SnO2 thin films by high-power pulsed magnetron sputtering. The oxygen ratio in the film may slightly differ from the oxygen partial pressure rate provided by the flowmeter. The resulting oxygen vacancies will cause lattice distortion affecting the mobility of charge carriers in the SnO2 film. Therefore, the oxygen partial pressure during the sputtering deposition process is the main factor affecting the conductivity of the SnO2 film.

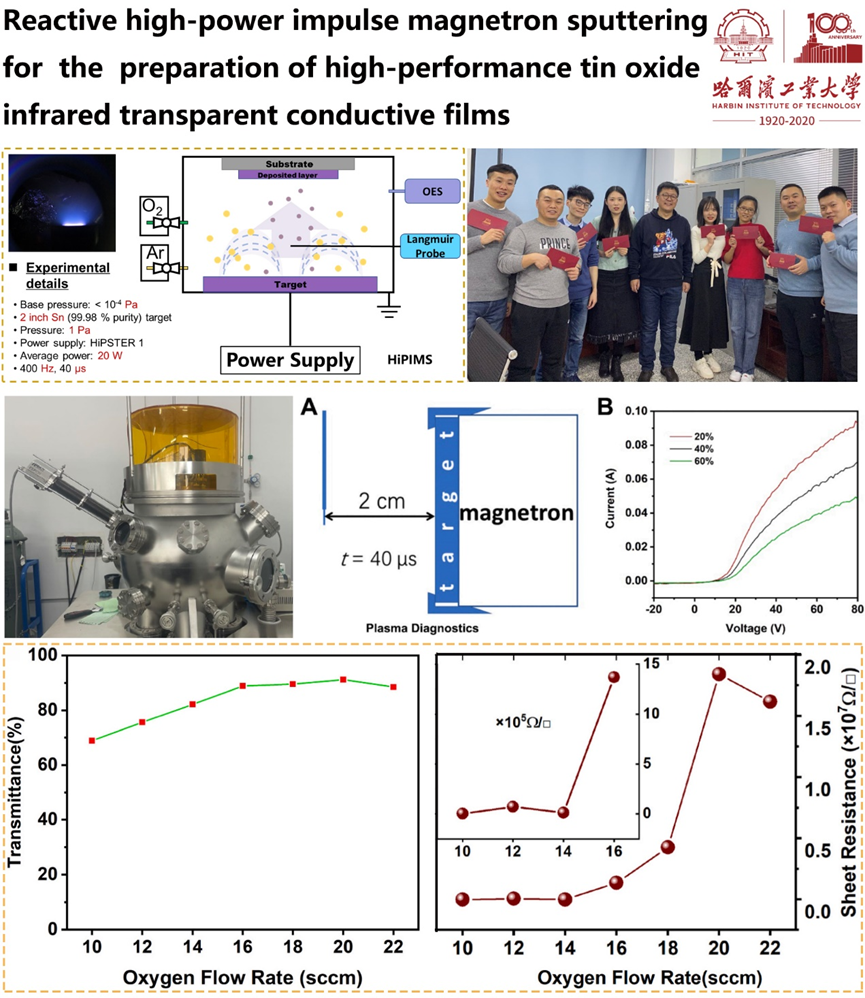

A research team lead by Prof. Jiaqi Zhu in Harbin Institute of Technology (HIT), investigating the reaction mode of high-power pulsed reactive magnetron sputtering and the crystal structure and infrared transparent conductive properties of SnOx thin films prepared at 600 °C. The effects of sputtering at different oxygen partial pressures from 10 to 24 sccm were examined. For SnOx films deposited at oxygen partial pressures of 10–14 sccm, the reaction mode was dominated by the metallic mode, and the polar unsaturated (101) plane was the preferred orientation of the film crystals. For SnOx films deposited at oxygen partial pressures of 16–18 sccm, the reaction mode was dominated by the transition mode, showing a preferred (110) plane orientation. In the deposition process, at oxygen partial pressure >18 sccm, the reaction proceeded in poisoning mode. As the oxygen partial pressure was increased, the carrier concentration decreased to 1.140 × 1015 cm-3, mobility increased to 14.93 cm2/Vs, and IR transmittance at 4 μm increased. Furthermore, excess O2 resulted in deteriorated electrical properties of the prepared SnOx films, with a maximum resistivity of 502.9 Ω·cm. In this process, the researchers used a commercial electrostatic Langmuir probe (ESPion, Hiden) to observe the state of the plasma at different stages. The measured probe current as a function of the voltage applied to the probe at several typical oxygen partial voltages. The core researchers also include Liangge Xu, a Ph.D. student of HIT. Dr. Lei Yang, the Department of Center of Analysis Measurement of HIT.

Project summary by: Jiaqi Zhu, National Key Laboratory of Science and Technology on Advanced Composites in Special Environments, School of Astronautics, Harbin Institute of Technology, Harbin 150080, PR China

Paper Reference: “Reaction mode-controlled crystal structure and optical and electrical properties of SnOx infrared transparent conducting films” Surface and Coatings Technology (2021) 422, 127506 https://doi.org/10.1016/j.surfcoat.2021.127506

Hiden Product: ESPion

Paper Reference: AP-ESPion-202111

To find out more about these products visit the ESPion product page or if you would like to contact us directly please Send us a Message.