We are focused on the preparation of advanced organosilicon nanostructures with controlled physicochemical properties enabling the binding of organic material with inorganic material. An example is the association of a polymer with glass, two incompatible materials, which must be joined by a strong covalent bond. The recent development of high-performance composite materials is associated with the synthesis of highly sophisticated nanostructures in which one material (polymer) is transformed into another material (glass) continuously without interfaces in the range of only 100 nm based on model simulations.

Organosilicon coatings are deposited by many types of techniques from liquid phase (e.g., dip coating, spray coating, spin coating, electrochemical techniques, self-assembled coating, Langmuir-Blodgett coating) or vapour phase (e.g., chemical vapour deposition (CVD), physical vapour deposition (PVD), atomic layer deposition (ALD), molecular layer deposition (MLD)). In most cases, the chemical and physical properties of organosilicon coatings depend on the technique used and the wet chemical techniques lead to coatings containing numerous atom-level imperfections that impair the ability to control properties of coatings. Among CVD techniques, plasma-enhanced CVD (PECVD) operated al low pressure has the technological potential to synthetize atomically accurate materials from small molecule fragments and/or individual atoms to control coating properties. However, the commonly used precursor-sufficient regime allows the properties of the coating to be controlled to a limited extent.

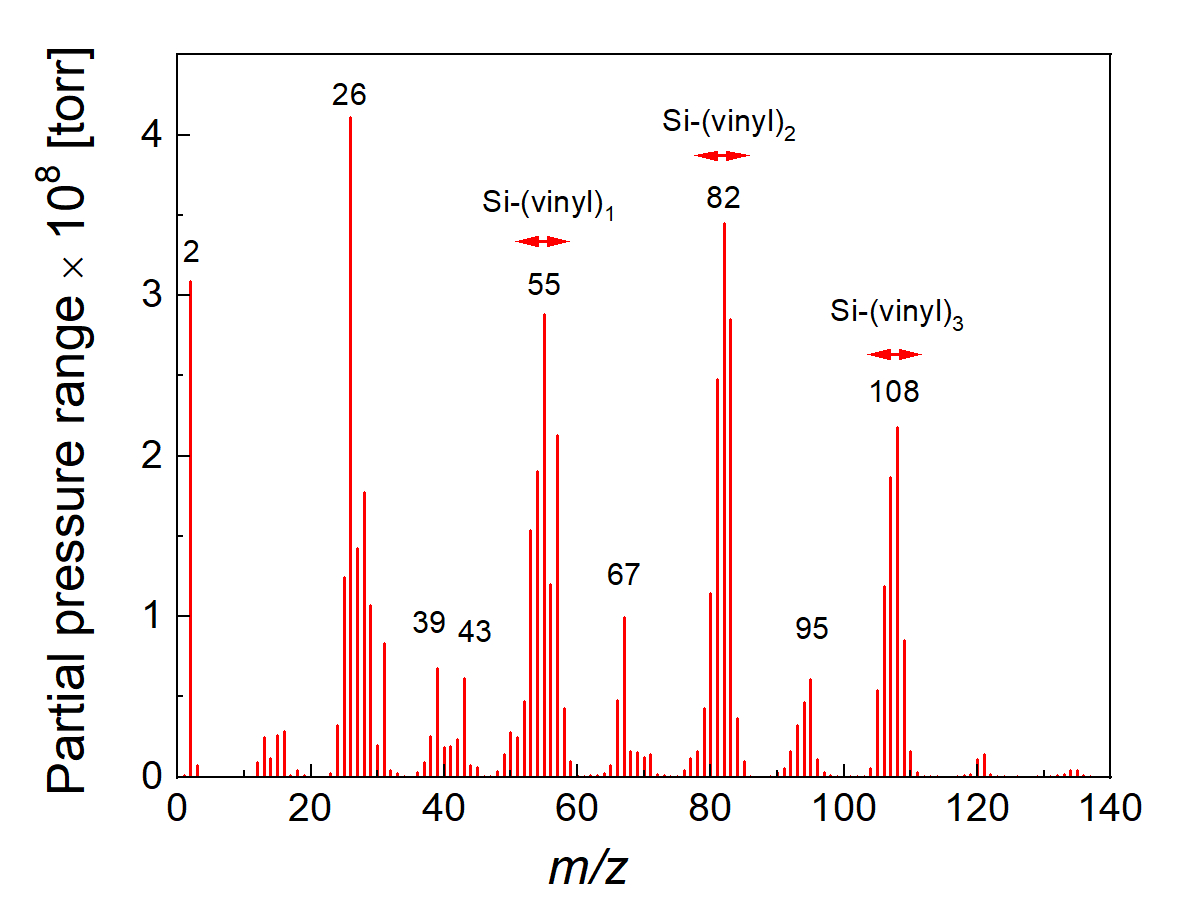

Electron impact mass spectrum of the neutral species in TVS plasma.

According to our recent studies, the precursor-deficient PECVD (plasma nanotechnology), based on controlled dissociation and consumption of the precursor molecule, can be used to control the physical properties of organosilicon coatings in dependence on their chemical properties, which is promising for further coatings development. Tetravinylsilane (TVS) was selected as the precursor molecule to demonstrate the range of coating properties achieved, from a polymer-like to a tough material with a gradually varying organic-inorganic character.

The power dependence of plasma species was investigated by mass spectrometry (Process Gas Analyser HPR-30, Hiden Analytical, UK) and the distribution of partial pressures, corresponding to the concentration of the fragments with a given mass number, showed that TVS molecules were fragmented into smaller and smaller species with enhanced effective power. The concentration of heavier species decreased significantly at higher power; one, two, three, and four vinyl groups were gradually detached from the TVS molecule, and even vinyl groups were dissociated into lighter reactive species (monoradicals, biradicals, and higher degree radicals or atoms, e.g., carbon) together with the elimination of hydrogen atoms. Thus, only by changing one deposition parameter, i.e., the effective power, we can control the elemental composition and the chemical structure of the deposited coatings based on plasma chemistry.

Materials Today Communication 2020, 24, 101234 DOI: https://doi.org/10.1016/j.mtcomm.2020.101234

Download Project Summary: AP-HPR-30-202001

Project summary by: Vladimir Cech, Institute of Materials Chemistry, Brno University of Technology, Purkynova 118, 61200 Brno, Czech Republic

To find out more about this product visit the HPR-30 product page or if you would like to contact us directly please Send us a Message.