Multi-principal element alloys (MPEAs) are alloys that consist of 5 or more elements with a concentration between 5 and 35 atom percent, and for which quite often a single phase with simple crystal symmetry is obtained. Where classical alloy design assumed the use of one principal element alloyed with fractions of other elements, this paradigm is changing. Indeed, MPEAs show that combinations of several elements in concentrated amount can lead to combinations of properties that are difficult to obtain with the classical alloy approach. A similar concept has also been applied for the synthesis of ceramic compounds, such as nitrides, carbides, borides, and oxides.

For nitride coatings the reported literature results show two remarkable results. First, many of the studied multi-component nitride coatings contain a majority of elements that do not form B1 (NaCl) structure nitrides and/or have a low chemical affinity for molecular nitrogen. Nevertheless, solid solution B1 structured nitride phases are formed in the multi-component coatings. The thin films, typically for magnetron sputter deposited coatings, have a fiber texture, i.e. they have a preferential out of-plane orientation. A second remarkable observation is that alloys that consist of weakly nitride forming elements show a <001> fiber texture, combined with a microstructure with V-shaped columns also known as a zone T microstructure. Thin films composed of strong nitride forming elements such as Ti, V, Hf, and Ta grown under similar conditions show for a similar microstructure a different, i.e. <111>texture.

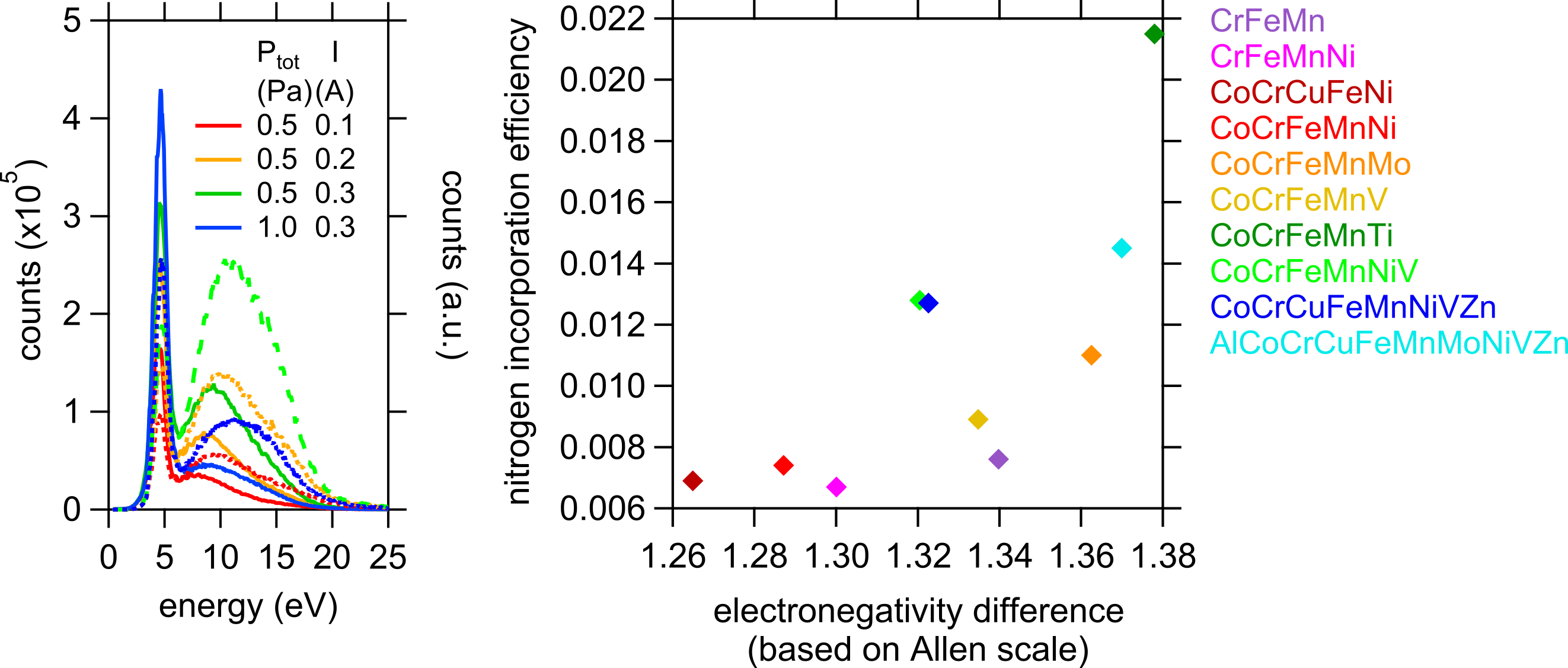

Left. Energy resolved spectra obtained during reactive magnetron sputtering using CoCrFeMNi powder target in an argon/nitrogen mixture under different conditions. The striped lines represent the re-calculated spectra to account for the transmission function. Right; The nitrogen incorporation efficiency as function of the electronegative difference between nitrogen and the average electronegativity of the constituent metals.

To understand this difference in textural evolution, nitrides based on multi-principal element alloys have been deposited by reactive magnetron sputtering from powder targets. All deposited nitrides were based on alloys of which the majority of the constituent metals have a low chemical affinity to molecular nitrogen (Co, Cu, Fe, Ni, Mn, and Zn). Some more reactive metals (Al, Cr, Ti, Mo, and V) were also added. The nitrogen incorporation in these alloys was investigated based on two different approaches. The incorporation efficiency is calculated based on the chemical composition of the deposited layer, and the metal flux towards the substrate. The calculations are based on a previous published model to simulate the reactive magnetron sputtering process. The observed trends are compared with results obtained from (energy resolved) mass spectrometry measurements (EQP, Hiden Analytical). Both methods proof that the nitrogen incorporation is dominated by sputtered nitrogen from the (partially) poisoned target. The composition weighted electronegativity average of the alloy constituent elements is used to assess the target poisoning level. It is shown that this electronegativity average correlates with the incorporation efficiency. The nitrogen incorporated in these alloys is mainly atomic nitrogen which affects the texture development. In contrast to nitrides based on highly reactive metals such as Ti which exhibit a cubic <111> fiber texture, a cubic <001> fiber texture is observed for the studied alloys. In conclusion, the reason for the different textural evolution between different MPEA based nitrides is related to the chemical reactivity towards nitrogen. Low reactivity materials grow due the incorporation of atomic nitrogen sputtered (or reflected) from the target.

Project summary by: Diederik Depla, Department of Solid State Sciences, Ghent University, Krijgslaan 281(S1), 9000 Gent, Belgium

Project summary by: Diederik Depla, Department of Solid State Sciences, Ghent University, Krijgslaan 281(S1), 9000 Gent, Belgium

Paper Reference: “Nitride formation during reactive sputter deposition of multi-principal element alloys in argon/nitrogen mixtures” Thin Solid Films (2021) 138721 doi.org/10.1016/j.tsf.2021.138721

Paper Reference: “Nitride formation during reactive sputter deposition of multi-principal element alloys in argon/nitrogen mixtures” Thin Solid Films (2021) 138721 doi.org/10.1016/j.tsf.2021.138721

Hiden Product: EQP

Project Summary Reference: AP-EQP-202124_Project Summary

To find out more about these products visit the EQP product page or if you would like to contact us directly please Send us a Message.