Low-energy inert-gas ion irradiation of the film surface during refractory transition-metal (TM) nitride growth by conventional DC magnetron sputtering has been used extensively to overcome the characteristically underdense microstructures with rough surfaces of layers deposited at low temperatures (Ts /Tm < 0.30, in which Ts is the film growth temperature and Tm is the melting point in K).[i] We recently demonstrated that high-power pulsed magnetron sputtering (HIPIMS) provides an alternative route for ion-assisted TM nitride film growth via the use of substrate bias, synchronized to the metal-rich portion of the plasma pulse. Stresses can be dramatically reduced, or even eliminated, since metal (as opposed to inert-gas) ions are components of the film.[ii],[iii]

Low-energy inert-gas ion irradiation of the film surface during refractory transition-metal (TM) nitride growth by conventional DC magnetron sputtering has been used extensively to overcome the characteristically underdense microstructures with rough surfaces of layers deposited at low temperatures (Ts /Tm < 0.30, in which Ts is the film growth temperature and Tm is the melting point in K).[i] We recently demonstrated that high-power pulsed magnetron sputtering (HIPIMS) provides an alternative route for ion-assisted TM nitride film growth via the use of substrate bias, synchronized to the metal-rich portion of the plasma pulse. Stresses can be dramatically reduced, or even eliminated, since metal (as opposed to inert-gas) ions are components of the film.[ii],[iii]

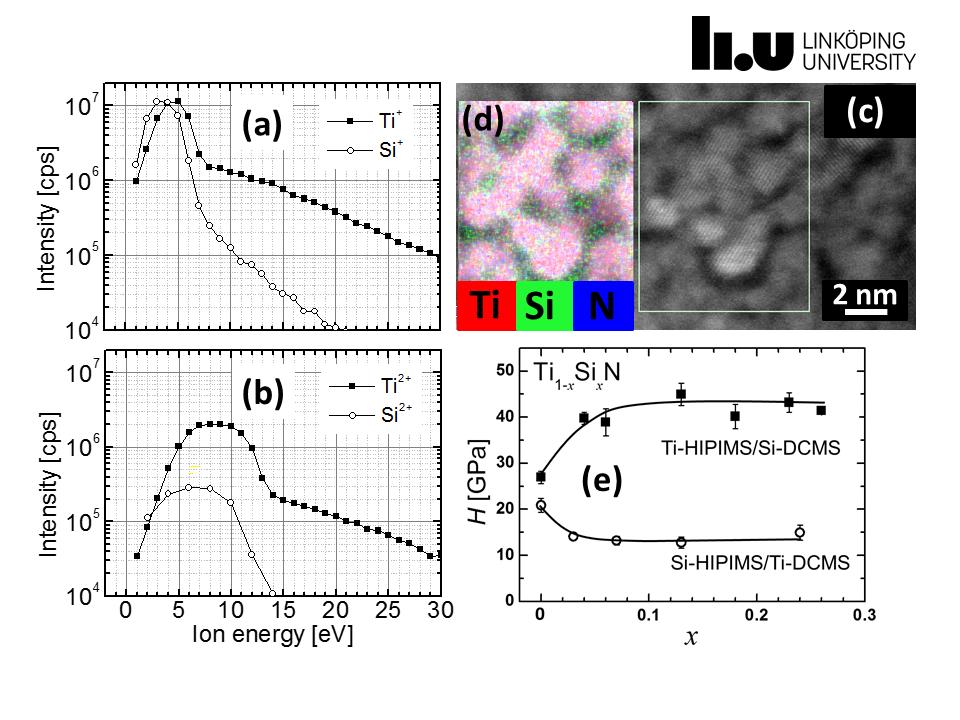

In this project we use a hybrid HIPIMS/DCMS two-target co-sputtering configuration, in which one target (either Ti or Si) is powered by HIPIMS while the other is powered by DCMS, for growth of Ti1‑xSixN films with compositions 0 ≤ x ≤ 0.26. Markedly different film growth pathways are obtained depending upon which target is powered by HIPIMS with, in both cases, a substrate bias applied in synchronous with the HIPIMS pulse. The observed divergence in film nanostructure, phase content, and mechanical properties between layers grown in Ti-HIPIMS/Si-DCMS and Si-HIPIMS/Ti-DCMS configuration is due to distinctly different metal-ion irradiation conditions, Ti+/Ti2+ vs. Si+/Si2+, during film growth, as determined by the ion mass spectrometry analyses performed at the substrate position with a Hiden Analytical EQP 1000 instrument (see Fig. 1(a)-(b)).

Figure 1. Ion energy distribution functions measured at the substrate position for (a) singly-charged Ti+ and Si+ ions, and (b) doubly-charged Ti2+ and Si2+ ions during Ti-HIPIMS and Si-HIPIMS pulses; (c) plan-view STEM micrograph, and (d) plan-view EDX/STEM elemental maps of a Ti0.74Si0.26N Ti-HIPIMS/Si-DCMS film, showing spatial distributions, acquired from the area outlined in panel (c); (e) nanoindentation hardnesses H(x) of Ti-HIPIMS/Si-DCMS and Si-HIPIMS/Ti-DCMS Ti1‑xSixN films grown on Si(001) substrates at Ts = 500°C.

A better mass match between incident Ti+ ions and the average film atomic mass, higher metal-ion/metal-atom ratios, and a high fraction of doubly-ionized species results in an average momentum transfer per deposited atom ~20 times higher for Ti-HIPIMS/Si-DCMS than during Si-HIPIMS/Ti-DCMS. As a consequence, adatom mean free paths are increased leading to the segregation of smaller Si atoms to column boundaries and the formation of a nanocomposite structure consisting of TiN-rich nanocolumns encapsulated in SiNx tissue phases (cf. plan-view STEM micrograph in Fig.1(c), and EDX/STEM elemental maps in Fig. 1(d)). Ti-HIPIMS/Si-DCMS Ti1‑xSixN films are superhard over a composition range that is significantly wider than reported previously, 0.04 ≤ x ≤ 0.26, with a maximum hardness, H = 45 GPa, for layers with x = 0.13 (see Fig. 1(e)). However, residual stresses are also high with an average value of ‑7±1 GPa.

In sharp contrast, during Si-HIPIMS/Ti-DCMS Ti1‑xSixN film growth, the flux of doubly-ionized metal ions is lower which, together with the lower mass of Si, low metal-ion/metal-atom flux ratio during HIPIMS pulses, and poorer mass match between incident Si+ ions and average film atomic mass results in relatively low values. As a consequence, Si is trapped in the metastable Ti1‑xSixN NaCl structure to form solid solutions over the highest compositional range yet reported, 0 ≤ x ≤ 0.24.

[1] I. Petrov, P.B. Barna, L. Hultman, J.E. Greene J. Vac. Sci. Technol. A 21 (2003) 117

[1] G. Greczynski, J. Lu, I. Petrov, J.E. Greene, S. Bolz, W. Kölker, Ch. Schiffers, O. Lemmer and L. Hultman, J. Vac. Sci. Technol. A 32 (2014) 041515.

[1] G. Greczynski, J. Lu, J. Jensen, I. Petrov, J.E. Greene, S. Bolz, W. Kölker, Ch. Schiffers, O. Lemmer and L. Hultman, J. Vac. Sci. Technol. A 30 (2012) 061504.

Project summary by: G. Greczynski, Thin Film Physics Division, Department of Physics (IFM)

Linköping University, SE-581 83 Linköping, Sweden

Paper Reference: G. Greczynski et al., (2015) “Control of Ti1−xSixN nanostructure via tunable metal-ion momentum transfer during HIPIMS/DCMS co-deposition”, Surface and Coatings Technology 280, 174-184 https://doi.org/10.1016/j.surfcoat.2015.09.001

Hiden Product: EQP

Reference: AP1140

To find out more about these products visit the EQP product page or if you would like to contact us directly please Send us a Message.