News & Press

View our Newsletter and Press Release archives.

Scinco Seminar on Hiden Quadrupole Mass Spectrometers

Professionals from various sectors, including academia, research, and industry, converged at a recent seminar to deepen their understanding of...

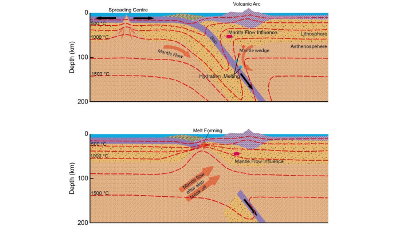

Advanced Dating Techniques Reveal Antarctic Peninsula’s Geological History

The thesis "Has the formation of a slab window below the Antarctic Peninsula controlled its topographic evolution?" broadly investigates the spatial...

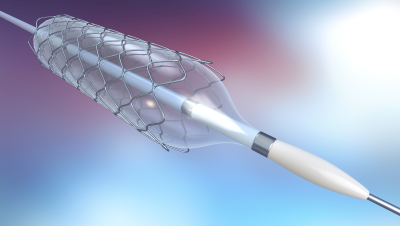

Revolutionising Cardiovascular Health: Monitoring the Surface Metallurgy of Stents

In a ground-breaking advancement for cardiovascular care, Hiden Analytical Ltd is proud to announce a surface measurement technique for devices...

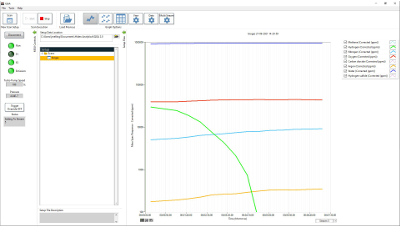

Advanced Software Package for QGA 2.0: MASsoft Professional and QGA 2 Software

Hiden Analytical Ltd is proud to announce the release of its advanced software package, combining MASsoft Professional and QGA 2 software, designed...

Hiden Analytical Ltd Unveils New e-Catalogue: Mass Spectrometers for Electrochemistry Applications

We're excited to announce a brand new e-Catalogue available on HidenAnalytical.com - brought to you by Hiden Analytical. Titled Mass Spectrometers...

Hiden Analytical Ltd Unveils Brochure for QGA 2.0 Next Generation Gas Analyser

Hiden Analytical Ltd proudly announces the release of its new brochure for the QGA 2.0, the latest advancement in gas analysis technology. The QGA...

Graduate Sales Engineer

We are seeking to recruit an enthusiastic Graduate Sales Engineer, with the opportunity for international travel. Working Mon-Fri as part of our dynamic sales team.

The Eruption in Iceland: Mass Spectrometry at the Forefront

Introduction The recent eruption on the Reykjanes Peninsula in Iceland has not only captivated observers with its raw natural beauty but also raised...

Advancing Catalyst Research: Unveiling the Hiden HPR-20 EGA System at Kairo Space

A Hiden Analytical HPR-20 EGA Evolved Gas Analyser, purchased by Kairospace, has recently been installed in at The University of Camerino, Italy by...