The Leibniz Institute for Surface Engineering Leipzig (IOM) gained matchless expertise on the fabrication and modification of ultra-precise and functional surfaces. In the 30 years of its history, HIDEN equipment were used for plasma and ion beam characterization (Figure 1). [1-4]

In the recent years, the method of broad beam ion etching has become indispensable in the manufacturing of functional and high-precision surfaces for optical applications. Ion beams used for this purpose consist of both inert and reactive species and are of Kaufman-type or use RF- or ECR- excitation. Due to the continuing increase of the processed sample size, the importance of long process times and, therefore, long maintenance intervals is rising. Due to the absence of hot and eroding filaments and a high plasma density, RF-excited ion beam sources are a promising variant concerning, low ion beam contamination, low maintenance, high ion beam currents and, consequently, shorter process times.

In order to maintain high quality etching results with a surface roughness in the sub-nm range, the processes occurring inside the ion beam source, but also along the way between the plasma and the etching sample must be understood. Therefore, it is essential to know the ion energy distribution functions (IEDFs) and, in case of the use of reactive gases (i.e. CHF3, CF4, SF6, O2) and mixtures thereof, the proportion of the different fragments of the reactive gas, i.e. the CFn, CHFn and SFn species, in the ion beam.

Figure 1: Typical configuration of an experimental setup with energy-selective mass spectrometer (EQP 300) at the Leibniz Institute for Surface Engineering. The setup was used for the characterization of a commercially available Kaufman-type ion beam source.

To characterize the ion beam concerning the mentioned parameters, we are using a HIDEN EQP300 energy-selective mass spectrometer (ESMS). For a first general understanding of the plasma processes in the ion beam source, we focused on the process gases Ar, He and Ne. The use of inert gases has the benefit of reducing chemical plasma processes and, therefore, reveal the physical characteristics of the ion production and extraction processes. For ion beam generation, we use a commercially available Scia RF-120m, that uses an inductively coupled plasma. [4]

Together with Faraday measurements, we showed that a high proportion of the extracted ions are affected by charge exchange processes with the residual gas of the vacuum chamber (≈30%-50%). These charge exchange processes produce slow ions and fast, high-energetic neutral atoms, which contribute to physical sputtering processes of the sample, but cannot be recorded by Faraday- or ESMS-measurements.

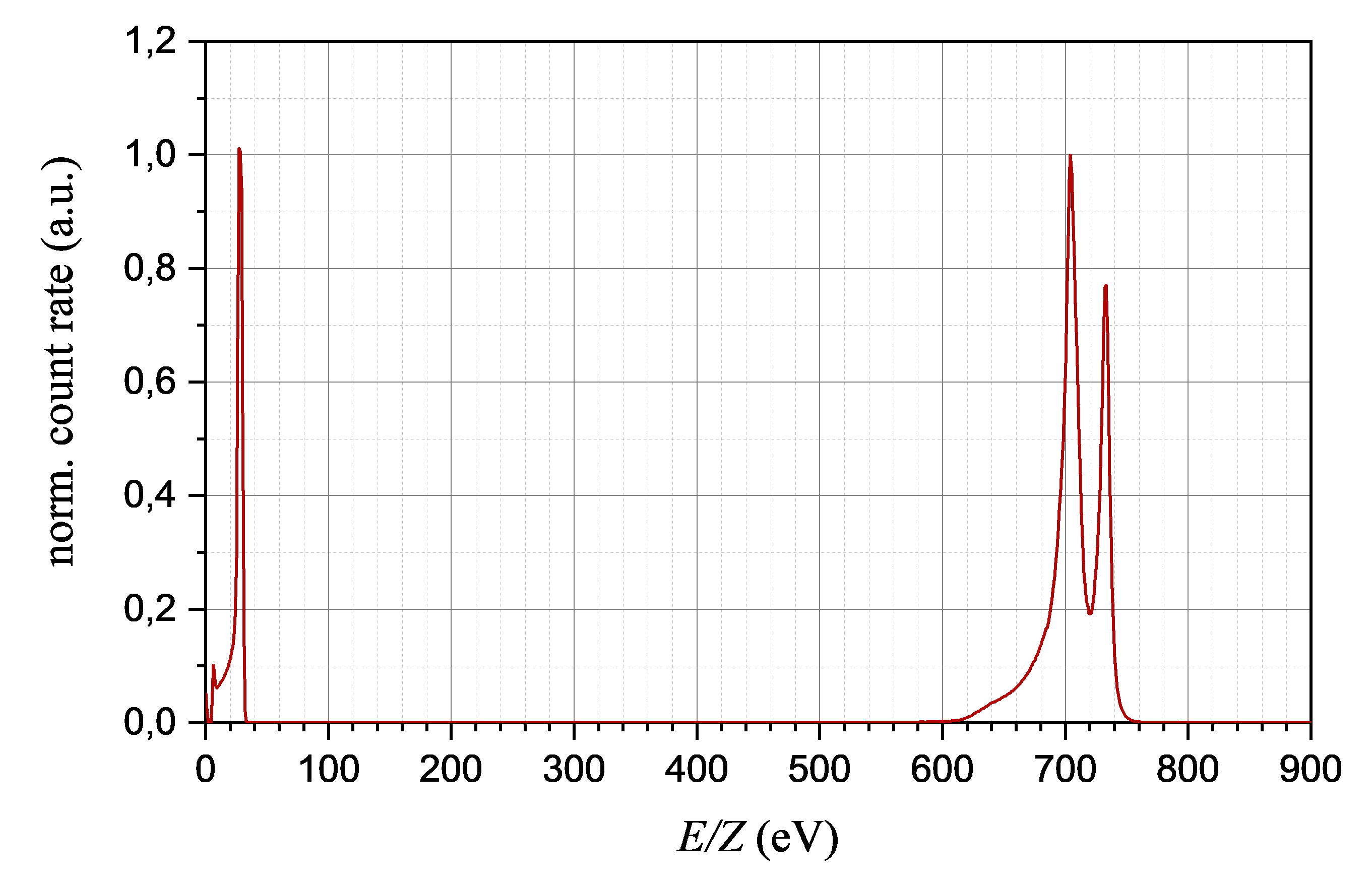

Figure 2: Ion energy distribution at M/Z = 40amu for the use of Ar as process gas. The spectrum shows a low-energy contribution at space charge potential of the ion beam, which can be related to charge exchange processes outside the ion beam source, and a bimodal high-energetic contribution originating from the plasma discharge inside the ion beam source.

The IEDFs reveal, that the high-energetic parts have a bimodal structure (see Figure 2). This may be related to HF-modulation effects of the plasma sheath potential due to a capacitive coupling of the plasma to the RF-coil.

The measurement of mass spectra at the main beam energy showed, that beside ions of the injected inert process gases, also eroded particles of the plasma discharge vessel, made of SiO2, and the extraction system, made of graphite, are present in the ion beam. This process may be amplified using reactive gases and, thus, have an unneglectable influence on the etching process. Future works will continue the measurement of the IEDFs, especially for using reactive gases.

Project summary by: Erik Rohkamm, Leibniz Institute of Surface Engineering (IOM), Permoserstr. 15 / 04318 Leipzig / Germany

Project summary by: Erik Rohkamm, Leibniz Institute of Surface Engineering (IOM), Permoserstr. 15 / 04318 Leipzig / Germany

Paper Reference: “Characterization of an RF excited broad beam ion source operating with inert gases” Journal of Applied Physics 129, 223305 (2021) https://doi.org/10.1063/5.0052758

References:

[1] Michael Zeuner, Jürgen Meichsner, Horst Neumann, Frank Scholze, Frieder Bigl, “Design of ion energy distributions by a broad beam ion source”, Journal of Applied Physics 80, 611-622 (1996) https://doi.org/10.1063/1.362869

[2] Michael Zeuner, Frank Scholze, Bernd Dathe, Horst Neumann, “Optimisation and characterization of a TCP type RF broad beam ion source”, Surface and Coating Technology, 142-144 (2001) https://doi.org/10.1016/S0257-8972(01)01219-1

[3] Thomas Amelal, Lukas Pietzonka, Erik Rohkamm, Carsten Bundesmann “Properties of secondary particles for the reactive ion beam sputtering of Ti and TiO2 using oxygen ions”, Journal of Vacuum Science & Technology A 38, 033403 (2020) https://doi.org/10.1116/1.5142911

[4] Erik Rohkamm, Daniel Spemann, Frank Scholze, Frank Frost, “Characterization of an RF excited broad beam ion source operating with inert gases”, Journal of Applied Physics 129, 23305 (2021) https://doi.org/10.1063/5.0052758

Hiden Product: EQP

Reference: AP-EQP-202126

To find out more about these products visit the EQP product page or if you would like to contact us directly please Send us a Message.