Integrated cyclic CO2 capture and in-situ hydrogenation to CH4 on dual function materials (DFMs) has attracted increasing interest in recent years, since it eliminates the costly CO2 purification step that is required for CO2 methanation on the continuous operation. The conventional DFMs are composed of a CO2 storage material (such as, Ca, Na, Mg or K) and a metal (mainly Ni or Ru) that assists its methanation. However, Ni presents lower activity and stability than Ru, whereas its high cost is the main limitation of the latter. Considering this background, the aim of this work is to evaluate the applicability of supported LaNiO3 perovskites, as precursors of efficient dual function materials for CO2 adsorption and in-situ hydrogenation to methane.

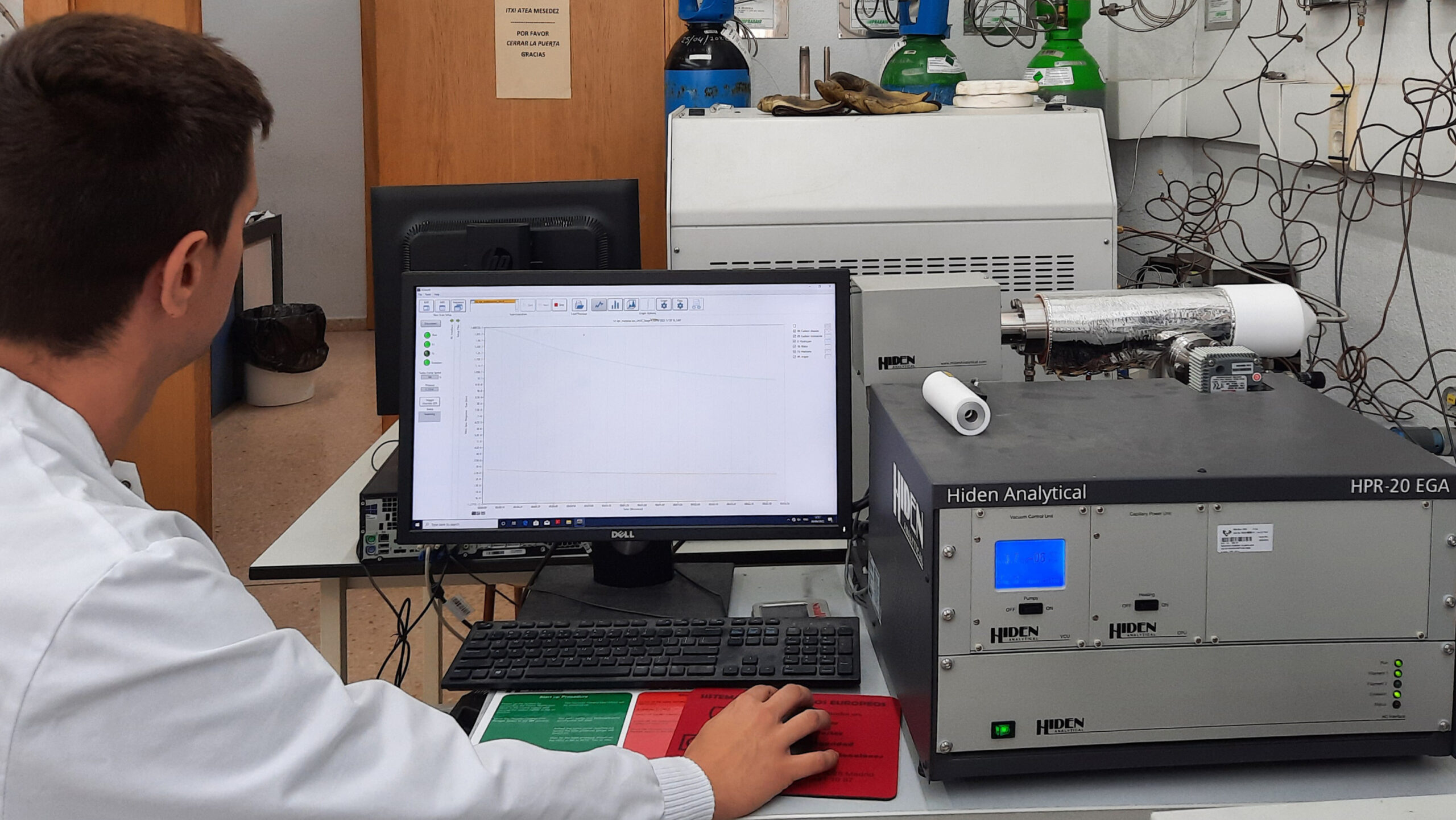

Four DFMs, obtained after the controlled reduction of different perovskite-based precursor (30% LaNiO3/CeO2, 30% LaNiO3/Al2O3, 30% LaNiO3/La-Al2O3 and LaNiO3), were prepared by combining citric acid and impregnation methods. The physico-chemical properties of the DFMs were determined by N2 adsorption-desorption, XRD analysis, STEM-EDX images as well as H2-TPR, H2-TPD and CO2-TPD experiments. All temperature programmed experiments were monitored with a Hiden Analytical HPR-20 EGA mass spectrometer. CO2 adsorption and hydrogenation cycles were carried out in a vertical stainless steel tubular reactor inside a 3-zone tube furnace. CO2, CH4, CO and H2O concentrations were continuously monitored by FTIR during the CO2 storage/capture period (10% CO2/Ar, 1 min) followed by its hydrogenation/methanation (10% H2/Ar, 2 min), with an intermediate Ar purge. The experiments were carried out with a flow rate of 1200 ml min-1 on the pre-reduced sample (550 or 800°C, 2h), in the 280-520°C temperature range.

The Hiden Analytical HPR-20 EGA Mass Spectrometer in the Laboratory

Results of XRD analysis, STEM-EDX images, H2-TPD, H2-TPR and CO2-TPD experiments reveal that the DFM obtained after reduction of 30% LaNiO3/CeO2 formulation shows the smallest Ni0 particle size (7 nm) and the highest medium-strong basic sites concentration. As a result, this DFM widens the operational window with respect to those obtained from 30% LaNiO3/Al2O3, 30% LaNiO3/La-Al2O3 and LaNiO3 formulation. Specifically, the resulting DFM maintains the methane production ranging between 80 and 103 µmol g−1 and the selectivity towards methane above 90% in the range of 280-520 °C. Based on characterization results, the best catalytic behaviour is related to a better contact between the different nature basic sites and the homogenously distributed Ni0 sites, which favours a fast spill-over of dissociated H to nearby CO2 adsorption sites. Note that these properties are significantly promoted with respect to conventional DFMs. The applicability of this DFM is further evidenced by a highly stable CH4 production during long-term experiments and a promoted Ni0/NiO reversibility in the absence/presence of O2 during the CO2 adsorption period, which allows a fast and complete recovery of CH4 production in absence of O2. These aspects favour a versatile application of the 30% LaNiO3/CeO2-based DFM formulation to convert CO2 outlet streams from combustion flue gases of different nature.

Project summary by: J.A. Onrubia-Calvo, A. Bermejo-López, S. Pérez-Vázquez, B. Pereda-Ayo, J.R. González-Velasco, Department of Chemical Engineering, Faculty of Science and Technology, University of the Basque Country UPV/EHU, Campus de Leioa, Barrio Sarriena, ES-48940 Leioa, Bizkaia, Spain

Project summary by: J.A. Onrubia-Calvo, A. Bermejo-López, S. Pérez-Vázquez, B. Pereda-Ayo, J.R. González-Velasco, Department of Chemical Engineering, Faculty of Science and Technology, University of the Basque Country UPV/EHU, Campus de Leioa, Barrio Sarriena, ES-48940 Leioa, Bizkaia, Spain

Paper Reference: “Applicability of LaNiO3-derived catalysts as dual function materials for CO2 capture and in-situ conversion to methane” Fuel 320 (2022) 123842. DOI: 10.1016/j.fuel.2022.123842

Hiden Product: HPR-20 EGA

Download PDF: AP-HPR-20-202319

To find out more about these products visit the HPR-20 EGA product page or if you would like to contact us directly please Send us a Message.