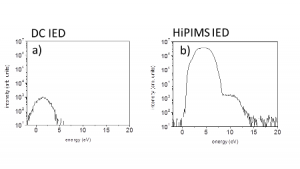

Nanoparticle-decorated carbon nanotubes (CNTs) are effective chemical and biological sensors, surfaces for heterogeneous catalysis, photovoltaics, and conformal thermal interface materials for electronics. The particle morphology on the CNT sidewalls strongly affects the properties and performance of metal-nanotube hybrids for such applications. Often nanoparticles are deposited by electrochemical methods, which generally require time consuming treatments with strong acid for surface defect production, which can result in a compromise of the intrinsic mechanical or transport properties of the CNTs, inhibiting their multi-functionality. We have examined physical vapor deposition techniques as scalable alternatives to electrochemical treatment for in situ growth of metal nanoparticles on the sidewalls of multi-wall carbon nanotubes (MWCNTs). Vapor phase growth of gold, nickel and titanium metal nanoparticles on multi-wall carbon nanotube (MWCNT) bucky paper was investigated. The size and distribution of nanoparticles was dependent on the intrinsic binding energy of the elemental metals, where metals with larger cohesive energies exhibited a higher nanoparticle density and smaller particle diameters. Particle diameters for any metal could be altered to mimic that of metals with different binding energies by in situ modification of the MWCNT surfaces by energetic metal ions (characterized with a Hiden EQP 1000 as shown in Figure 1) during their growth, where removal of a carbon atom from a MWCNT surface requires incident ions kinetic energies > 5-7 eV. Control of the ariel density, diameter and morphology of metal nanoparticles grown on as-received and annealed multi-walled carbon nanotube sidewalls by sputtering was demonstrated for gold, nickel and titanium.

Figure 1: Au+ ion energy distributions measured for (a) dc and (b) HiPIMS processing conditions.

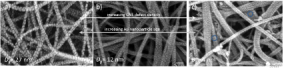

A range of average gold particle diameters from approximately 5-30 nm could be produced depending on the intrinsic sputter process parameters (especially metal ion flux and kinetic energy) and defect density of the MWCNT surfaces which could also be controlled by annealing prior to sputtering (Figure 2). Particle characteristics could also be altered with temperature, total incident ion flux during processing, or by initial CNT diameters. The diameter of the MWCNTs had a significant influence on the geometry of the nanoparticles. Particles were elongated along the nanotube axis for tube diameters <30 nm. Remarkably strong alignment of the particles along the nanotube axis was observed, especially for MWCNTs with higher defect densities. The PVD process used to grow the nanoparticles is easily scalable to large arrays of CNTs, and will be explored for adding multi-functionality to CNT-based nanocomposites.

Figure 2: Scanning electron micrographs and accompanying Raman spectra for (a) annealed buckypaper with dc nanoparticle growth, (b) annealed buckypaper with HiPIMS growth, and (c) as-received buckypaper with HiPIMS growth.

Project Summary by:

Christopher Muratore

Department of Chemical and Materials Engineering

University of Dayton

300 College Park

Dayton OH 45469-0240

USA

Visit Product Page : EQP

View Full Newsletter : Mass Spectrometers for Plasma Characterisation

Make an enquiry : Send us a message