Understanding the fundamentals processes involved in thin film nanostructuration is nowadays a key issue in material science and technology. In this aspect, plasma-assisted deposition of thin films is relevant thanks to the strong interaction between plasma-generated species and the film during growth, which may induce the formation of metastable structures which optimize or provide singular properties for diverse applications. In project PLASMATER (P10-FQM-6900), funded by the Junta de Andalucía, we aim at studying these fundamental processes and their influence on the film nanostructure. For this, film characterization techniques such as scanning electron microscopy, atomic force microscopy, optical response measurements, etc. have to be combined with plasma diagnosis techniques, such as optical emission spectroscopy, Langmuir probe measurements or mass spectrometry. We have available an energy-resolved mass spectrometer (EQP 500 HIDEN Analytical Ltd.) which has helped us understand the role of ion impingement on the growth of SiO2 thin films deposited by DC pulsed magnetron sputtering.

In DC pulsed magnetron sputtering discharges, positively charged ions are produced in the plasma bulk and accelerated towards the film with kinetic energies of few electronvolts when the substrate is not biased. Although their role in thin film nanostructuration could be relevant in some cases, their typical energy is about the displacement energy threshold of the adatoms in the material, and, most likely, they heat up the film surface and weakly induce thermally activated relaxation processes. On the other hand, negative ions, which are present when an electronegative gas is introduced in the reactor, may be generated at the cathode surface and accelerated towards the film with energies of the order of the cathode potential fall (i.e., few hundred electronvolts). These ions possess enough energy to induce the mobilization of the film adatoms through collisions and cause important changes in the film nanostructure. Although from an energetic point of view negative ions are relevant, the question on whether their flux is high enough to actually produce changes in the film was still open until this paper appeared.

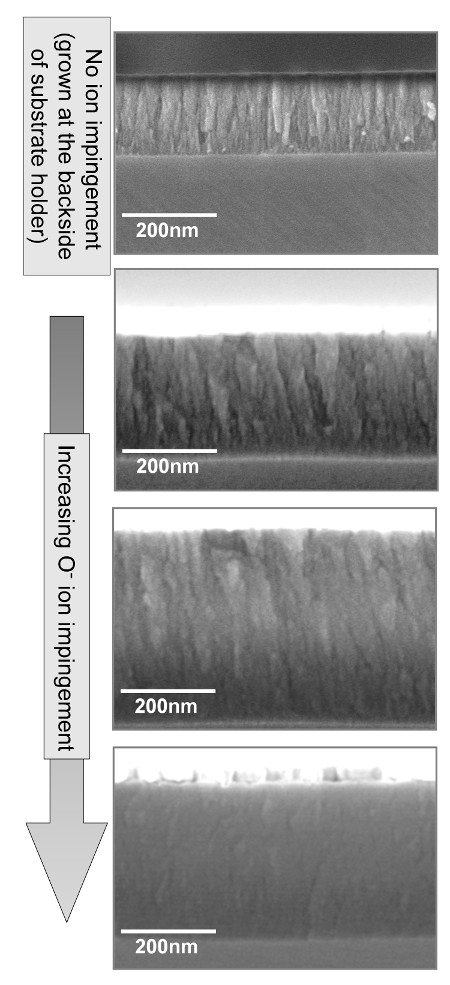

Cross-sectional electron microscopy images of the films for increasing O– flux

Cross-sectional electron microscopy images of the films for increasing O– flux

In this publication we show that negative oxygen ions are responsible for microstructural changes on magnetron sputtered SiO2 thin films. For this, we have deposited several coatings under wisely-chosen conditions with different microstructures. After analyzing the role of the relevant processes affecting the growth of the films, such as surface shadowing, thermally activated processes on the surface as well as positive and negative ion impingement, we conclude that the obtained microstructural changes can only be attributed to the impingement of intermediate energy O– ions. These ions appear in the discharge as a product of the dissociation of high-energy molecular oxygen negative ions produced near the cathode surface and that are accelerated towards the plasma. In the image we depict four cross-sectional scanning microscopy images of the films deposited for increasing O– ion flux bombardment. There, the removal of vertical geometrical patterns and void percentage for increasing negative oxygen fluxes are apparent. Overall, we show the existence of two thin film nanostructuration regimes at low temperatures, controlled by the amount of O2 in the deposition reactor and caused by the competition between the surface shadowing mechanism and the negative ion-induced adatom surface mobility processes.

Paper Reference: Macias-Montero et al. (2012) “Influence of plasma-generated negative oxygen ion impingement on magnetron sputtered amorphous SiO2thin films during growth at low temperatures” Journal of Applied Physics 111 (5) 054312 http://dx.doi.org/10.1063/1.3691950

Hiden Product: EQP Mass and Energy Analyser

Read Full Article: Customer Research Review Issue 1120/09 Thin Films, Plasma and Surface Engineering