Surface Analysis of Energy Materials

The challenges with manufacturing and failure analysis of a new generation of energy materials has necessitated novel techniques for analysing process quality and failure analysis. In lithium battery research, SIMS is particularly important in investigations of ageing at the anode/ electrolyte interface. During the first two cycling processes, a solid electrolyte interface is formed on the anode surface, this has dynamic changes in both composition and structure as the cell ages. SIMS, investigations allow for this interface layer to be characterised and quantified. With monolayer depth resolution and excellent low mass transmission, in contrast to other techniques such as EDS and XPS, SIMS is ideal for this task.

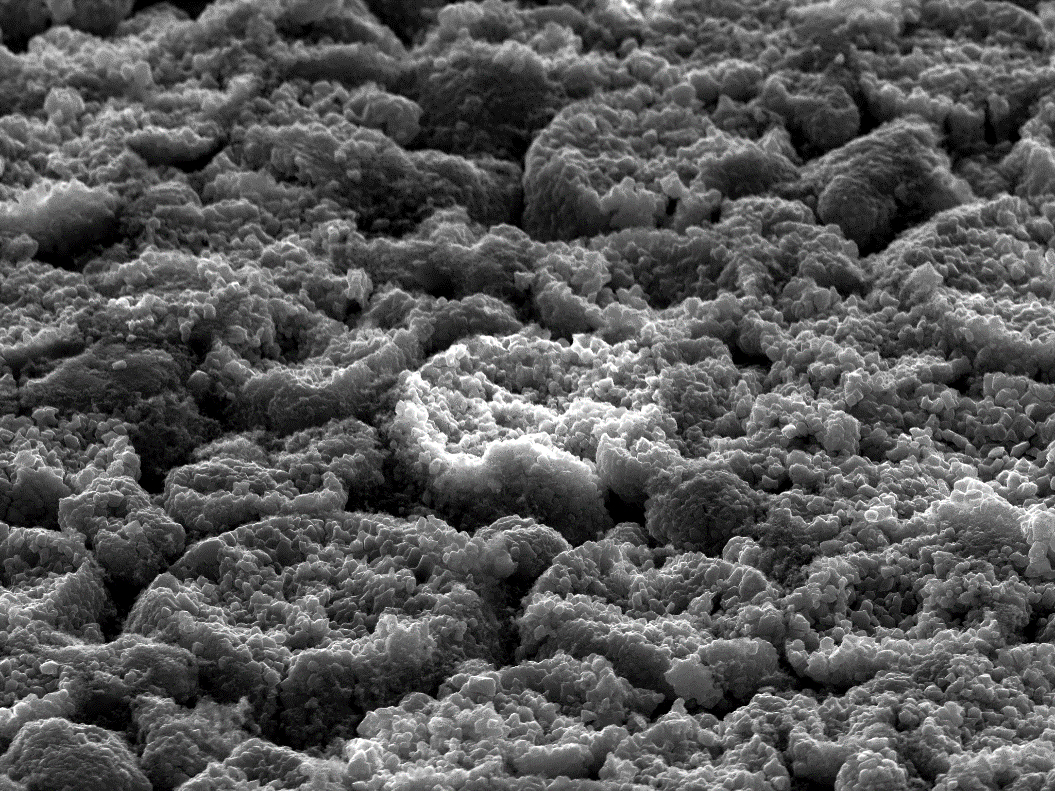

With precise sampling depth and low mass performance, SIMS is an excellent tool to investigate energy materials. When coupled with a FIB-SEM, Focussed Ion Beam Scanning Electron Microscope, the benefits are further enhanced. The primary ion beam of the FIB-SEM can be controlled by the SIMS software, giving an analytical field of view equivalent to the SEM image. This ‘correlative microscopy’ allows for direct chemical analysis of specific surface features as well as layer structures, contaminants, corrosion, adhesion problems etc with elemental data to the ppm level able to be displayed along with the SEM images.

Applications

This technique is broken down into two distinct methodologies: dynamic and static SIMS. Each of these uses a primary ion beam that impacts a sample in vacuum conditions, causing extremely small volumes of material to be ablated from the surface – a fraction of this ejected material will be ionised. These secondary ions are acquired by the sample inlet of the mass spectrometry unit to develop a robust understanding of the composition of the specimen’s uppermost surface layers.

The primary difference between dynamic and static SIMS is the ion dosage (a higher dose for dynamic SIMS instruments), and that dynamic SIMS cannot be run with a defocussed ion beam; it must be raster scanned across the sample surface to produce a flat-bottomed crater. Hiden Analytical’s SIMS workstation can perform both dynamic and static SIMS analysis in a single consolidated SIMS instrument. With a dual-mode MAXIM mass spectrometer, the SIMS workstation can operate in secondary ion detection mode for +ve/-ve ion detection, and in a secondary neutral detection mode for +ve data quantification. Each mode is compatible with mass range options up to 5000 atomic mass units (amu).

Hiden Analytical’s SIMS Workstation

Our SIMS workstation is a comprehensive solution for depth profiling and compositional analysis of samples in various areas of surface analysis, thin film engineering, nanotechnology, fuel cell research, and more. The system is highly customizable to suit the unique requirements of users in complex fields.

How to Analyse the Top Nano Layers of a Material

If you need more information about performing static or dynamic SIMS analysis, browse our product literature and presentations. For a more detailed insight into the features of our SIMS workstation, simply contact a member of the Hiden Analytical team today.

Instruments for diagnostics and analysis of thin films

Analysis of Metal-Polymer Interfaces in Thin Film Capacitors by Dynamic Quadrupole SIMS

Analysis of MOCVD-Grown GaInP/Ga(ln)As/Ge Triple Junction Solar Cells by SIMS

- 3D imaging

- depth profiling with highly flexible gating

- simple choice of species

- easy set-up for inexperienced users yet full control for experts

- large live interactive image and depth profile windows

- export in .csv and proprietary formats